Unlocking the Potential of Thermal Graphite Film in Modern Electronics

The advent of modern electronics has ushered in a new era of innovation, where efficiency and performance are paramount. Among the emerging materials revolutionizing this landscape is Thermal Graphite Film, a remarkable substance known for its exceptional thermal conductivity and lightweight properties. As electronic devices continue to shrink in size while demanding higher performance, the need for effective thermal management solutions has never been more critical. Thermal Graphite Film stands out as a key enabler in this quest, providing superior heat dissipation capabilities that enhance the reliability and lifespan of electronic components. This article explores the multifaceted applications of Thermal Graphite Film in various electronic devices and systems, highlighting its potential to unlock new possibilities in the design and functionality of next-generation technologies. As we delve into the benefits and challenges associated with its implementation, we aim to illuminate how Thermal Graphite Film can drive the evolution of modern electronics towards a more efficient and sustainable future.

Exploring the Unique Properties of Thermal Graphite Film in Electronics

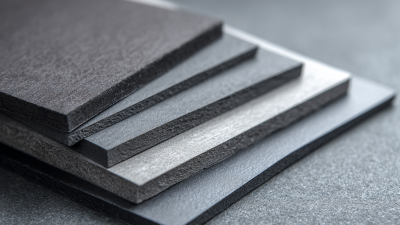

Thermal graphite film is emerging as a crucial material in modern electronics, thanks to its exceptional thermal conductivity and lightweight characteristics. According to a report by IDTechEx, the demand for thermally conductive materials in the electronics sector is projected to grow at a CAGR of 7.5%, reaching approximately $2.7 billion by 2026. This growth can be attributed to the increasing need for efficient thermal management solutions in compact electronic devices such as smartphones, laptops, and electric vehicles.

One of the unique properties of thermal graphite film is its anisotropic thermal conductivity, which allows it to effectively transfer heat in one direction while maintaining a lightweight and thin profile. This feature is particularly beneficial for high-performance applications where space is limited. In addition, a study from TechInsights indicates that thermal graphite film can achieve thermal conductivity levels exceeding 1000 W/m·K, significantly outperforming traditional thermal interface materials like thermal paste or silicon-based compounds. As electronic devices become increasingly powerful, the role of thermal graphite film in enhancing performance by managing heat dissipation cannot be overstated.

The Role of Thermal Conductivity in Enhancing Device Performance

Thermal conductivity plays a crucial role in modern electronics, particularly as devices become increasingly compact and powerful. As the demand for higher performance in electronic systems rises, effective thermal management strategies are essential to prevent overheating and maintain optimal functionality. Thermal graphite film emerges as a superior solution due to its exceptional thermal conductivity properties, enabling efficient heat dissipation and improving overall device reliability.

In applications ranging from smartphones to high-performance computing systems, the integration of thermal graphite film contributes significantly to device performance. Its ability to conduct heat away from critical components allows for sustained operation under demanding conditions, reducing the risk of thermal throttling. Furthermore, the lightweight nature and flexibility of thermal graphite film enable seamless incorporation into various form factors, facilitating innovative designs and enhancing energy efficiency. By unlocking the potential of thermal graphite film, manufacturers can meet the evolving thermal demands of next-generation electronics, ultimately leading to more reliable and high-performing devices.

Applications of Thermal Graphite Film in Heat Management Solutions

The use of thermal graphite film (TGF) in modern electronics is rapidly gaining traction, especially in heat management solutions. According to a report by MarketsandMarkets, the thermal management market is expected to reach $16.4 billion by 2025, with technologies like TGF playing a crucial role in this growth. TGF's exceptional thermal conductivity, which can exceed 1500 W/mK, makes it an ideal material for devices that require efficient heat dissipation. This performance surpasses traditional materials like copper and aluminum, offering a lighter and slimmer alternative that can be integrated seamlessly into compact electronic devices.

Moreover, applications of TGF are particularly prominent in the smartphone and electric vehicle markets, where thermal management is vital for operational efficiency and device reliability. The research conducted by IDTechEx highlights that innovative thermal solutions, including TGF, can reduce the overall weight of thermal systems by up to 30%. This reduction is critical in enhancing battery life and performance in electric vehicles and portable electronics, aligning with the industry's push towards more sustainable and energy-efficient technologies. As the demand for high-performance electronics continues to rise, TGF stands out as a promising material that addresses heat management challenges while contributing to device innovation.

Unlocking the Potential of Thermal Graphite Film in Modern Electronics - Applications of Thermal Graphite Film in Heat Management Solutions

| Application Area | Thermal Conductivity (W/m·K) | Thickness (mm) | Benefits |

|---|---|---|---|

| Consumer Electronics | 2000 | 0.1 | Efficient heat dissipation, lightweight, flexible |

| LED Lighting | 1800 | 0.2 | Enhanced light output, longer lifespan |

| Power Electronics | 1500 | 0.3 | Increased reliability, reduced thermal resistance |

| Automotive Systems | 1700 | 0.25 | Optimized thermal management, durable under high temperatures |

| Telecommunications | 1600 | 0.15 | Reliable performance in compact spaces |

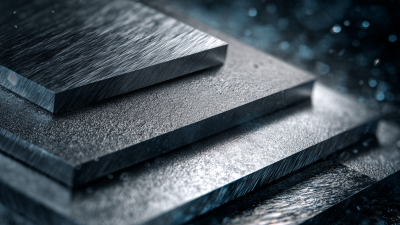

Comparative Analysis: Thermal Graphite Film vs. Traditional Materials

The emergence of thermal graphite film technology has sparked significant interest in the electronics industry, primarily due to its superior thermal conductivity compared to traditional materials. For instance, studies show that thermal graphite films can achieve thermal conductivity levels exceeding 600 W/mK, while common materials such as aluminum and copper typically range between 200-400 W/mK. This enhanced thermal management capability is crucial for modern devices, which often experience high heat densities, particularly in high-performance computing and power electronics applications.

Furthermore, thermal graphite films are remarkably lightweight and thin, making them an attractive alternative to traditional thermal interface materials that look bulky and can add weight to sensitive devices. Reports have indicated that adopting thermal graphite films can reduce overall device weight by up to 30%, improving portability and efficiency. These benefits have led to a growing adoption of thermal graphite films in high-end electronic products, with market research forecasting a compound annual growth rate (CAGR) of around 15% for this technology over the next five years, driven by the increasing demand for efficient thermal management solutions in various electronic applications.

Future Innovations: The Path Forward for Thermal Graphite Film in Electronics

The future of thermal graphite film in electronics promises to be transformative, paving the way for advanced thermal management solutions. With the increasing demand for higher performance and miniaturization in electronic devices, the ability of thermal graphite film to efficiently dissipate heat becomes essential. Its lightweight and flexible properties open avenues for innovative designs that can enhance the reliability and lifespan of various electronic components, from smartphones to high-performance computing systems.

Innovations in manufacturing processes, such as improved layer alignment and purity, are crucial to maximizing the potential of thermal graphite film. Researchers are exploring the integration of intelligent temperature-sensitive functionalities that could adapt to varying operational conditions. Furthermore, collaboration between material scientists and electrical engineers will facilitate the development of hybrid systems that leverage thermal graphite film alongside other advanced materials, creating smarter and more efficient thermal management solutions. This synergy will not only enhance device performance but also contribute to sustainability efforts by reducing the need for heavier and less efficient cooling methods.

Related Posts

-

Exploring the Future: Advances in Graphite Thermal Film Technology by 2025

-

Understanding Industry Standards and Reasons Behind the Best Graphite Thermal Sheet Selection

-

Ultimate Guide to Sourcing Thermal Graphite Sheets for Enhanced Thermal Management Solutions

-

How to Choose the Right Graphite Thermal Sheet for Your Application

-

Exploring Market Trends: Thermal Graphite Sheets at the 138th Canton Fair 2025 in China

-

Global Market Trends and Insights for Best Graphite Paper by 2025 with Real World Applications