How to Choose the Right Thermal Graphite Film for Your Application

When selecting materials for thermal management applications, the importance of choosing the right Thermal Graphite Film cannot be overstated. This specialized film is known for its excellent thermal conductivity, flexibility, and lightweight properties, making it an ideal choice for a wide range of industries, including electronics, automotive, and aerospace. However, with various types and specifications available on the market, navigating the selection process can be challenging.

Understanding the unique requirements of your application is crucial in determining the right Thermal Graphite Film to utilize. Factors such as thermal performance, operational environment, and mechanical characteristics play a significant role in making the best choice. In this guide, we will explore the essential considerations to keep in mind when selecting Thermal Graphite Film, ensuring that your application is optimized for efficiency and effectiveness. From thermal conductivity ratings to thickness and adherence properties, we will provide insights to help you make an informed decision, thereby enhancing the overall reliability and performance of your systems.

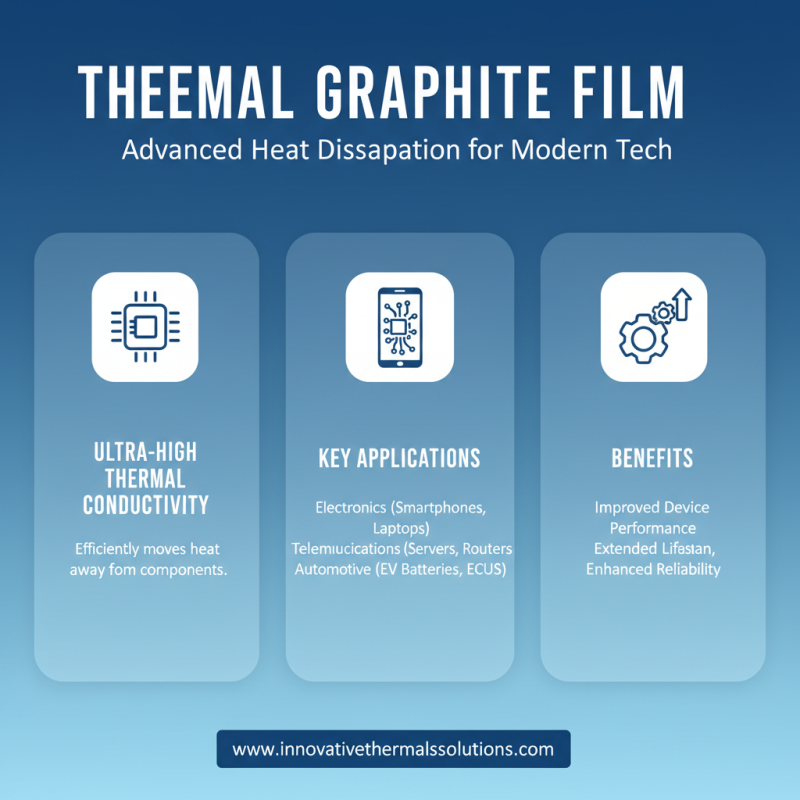

Understanding Thermal Graphite Film and Its Applications

Thermal graphite film is a highly versatile material known for its remarkable thermal conductivity properties, making it an ideal choice for various applications across multiple industries. This film is composed of thin layers of graphite, which facilitate efficient heat dissipation, ensuring optimal performance and longevity of electronic devices. In settings where heat management is crucial—such as in electronics, telecommunications, and automotive industries—thermal graphite films act as effective thermal interface materials (TIMs) that improve the thermal performance of components by enhancing thermal contact resistance and facilitating better heat flow.

When considering thermal graphite film for specific applications, it is essential to understand the unique requirements of each use case. Key factors to evaluate include thermal conductivity, thickness, and mechanical flexibility. For high-power devices that generate considerable heat, films with higher thermal conductivity ratings are preferable to efficiently transfer heat away from critical components. Additionally, the film's thickness can influence not only its thermal performance but also its ease of integration within existing designs. Lastly, mechanical flexibility allows for better adaptation to various shapes and surfaces, making it suitable for use in compact or irregularly shaped devices. Understanding these parameters ensures the selection of an optimal thermal graphite film tailored to meet specific application demands.

Key Factors to Consider When Selecting Thermal Graphite Film

When selecting the right thermal graphite film for your application, various key factors must be considered to ensure optimal performance. First, it's essential to evaluate the thermal conductivity of the film. Thermal graphite films are often chosen for their superior heat dissipation properties, so examining the thermal conductivity rating relevant to your specific application is crucial. Higher conductivity typically means better performance, but it can also come at an increased cost.

Another vital factor is the thickness of the film. The thickness can influence both the flexibility and the thermal performance of the material. Thicker films may offer enhanced durability but could also reduce the overall thermal transfer efficiency in certain applications. It's advisable to consider the dimensional constraints within your design when assessing the thickness and ensure that it aligns with your thermal management needs.

**Tip:** Always conduct preliminary tests with samples of different thicknesses and conductivities to see which combination works best for your application in real-world scenarios.

Additionally, consider the environment in which the thermal graphite film will be used, including temperature ranges and exposure to chemicals or moisture. Ensuring that the material can withstand the specific environmental conditions will prevent premature failure and enhance longevity.

**Tip:** It's beneficial to consult technical datasheets and application examples to gain insights into how thermal graphite films perform in settings similar to yours.

Thermal Conductivity of Various Thermal Graphite Films

Types of Thermal Graphite Films and Their Specific Uses

Thermal graphite films are increasingly recognized for their exceptional heat dissipation properties, making them integral in a variety of applications across many industries. Primarily, these films are categorized based on their thermal conductivity, thickness, and composition, aligning with specific operational needs. For instance, high thermal conductivity films, generally exceeding 1000 W/mK, are ideal for demanding applications such as power electronics and LED cooling, where efficient heat management is critical to performance and longevity.

Additionally, there are specialized films designed for use in flexible electronic devices and wearables. These films combine excellent thermal management with mechanical flexibility, allowing for seamless integration in compact spaces. Reports from industry analysts indicate that the demand for flexible thermal management solutions is expected to grow at a CAGR of over 8% through 2025, driven by the surge in consumer electronics and the automotive sector’s push towards electric vehicles. Therefore, selecting the appropriate type of thermal graphite film is essential, as it directly influences device performance and reliability, catering to the unique requirements of each application.

How to Choose the Right Thermal Graphite Film for Your Application

| Type of Thermal Graphite Film | Thermal Conductivity (W/mK) | Thickness (µm) | Typical Applications |

|---|---|---|---|

| High Thermal Conductivity Film | 1200 | 50 | LEDs, Power Modules |

| Standard Thermal Film | 800 | 100 | Consumer Electronics, CPUs |

| Ultra-thin Thermal Film | 600 | 25 | Mobile Devices, Wearables |

| Flexible Thermal Film | 750 | 75 | Automotive, Aerospace Applications |

| High-Temperature Thermal Film | 900 | 50 | Industrial Equipment, HVAC |

Comparative Analysis of Performance Metrics in Thermal Graphite Films

When selecting the appropriate thermal graphite film for a specific application, performance metrics such as thermal conductivity, thickness, and flexibility are vital parameters to consider. According to a recent report by the Global Graphite Market Analysis, high-performance thermal graphite films can achieve thermal conductivities ranging from 300 to 2000 W/m·K. This variance is influenced by the orientation of graphite flakes and the manufacturing process, playing a crucial role in heat dissipation applications, especially in the electronics and automotive industries where efficient thermal management is paramount.

Comparative analysis of different thermal graphite films shows that films with varying thicknesses can significantly impact overall performance. Thicker films, typically over 100 microns, may provide better thermal conductivity but can increase thermal resistance due to their mass. Conversely, thinner films, around 20-50 microns, excel in applications requiring flexibility and conformability, such as in compact electronic devices. Furthermore, a study published in the Journal of Materials Science indicates that the mechanical flexibility of thermal graphite films can enhance their applicability in curved surfaces, thereby broadening their use in cutting-edge technologies like wearable electronics and advanced thermal interface materials.

Guidelines for Sourcing and Testing Thermal Graphite Film Products

When sourcing thermal graphite film products, it is essential to consider various factors that will influence your application's performance. Start by assessing the thermal conductivity required for your specific needs. Different applications may demand varying levels of heat dissipation, so ensure you select a film that meets or exceeds these requirements. It’s also crucial to evaluate the film’s thickness, as it affects both flexibility and thermal resistance. Thinner films may be more appropriate for compact designs, while thicker films might provide better insulation in specific contexts.

Testing is another vital aspect of the sourcing process. Conducting proper thermal testing will allow you to verify the film's performance under actual operational conditions. Utilize techniques such as thermal imaging or temperature profiling to assess the efficiency of the film in managing heat transfer. Additionally, mechanical testing, including adherence and shear strength tests, will help determine how well the film can endure physical stress in your application.

Engaging with suppliers who offer testing services or sample products for evaluation can provide valuable insights and help ensure that you make a well-informed decision for your thermal management needs.

Related Posts

-

Top 10 Thermal Graphite Sheet Manufacturers from China at the 137th Canton Fair

-

China's Leading Edge: The Evolution of the Best Graphite Thermal Sheets in Global Manufacturing

-

Innovative Applications of Graphite Thermal Film in Modern Electronics

-

Exploring Market Trends: Thermal Graphite Sheets at the 138th Canton Fair 2025 in China

-

Unlocking the Potential of Thermal Graphite Film in Modern Electronics

-

Unlocking Performance Enhancements with Best Graphite Thermal Film Benefits