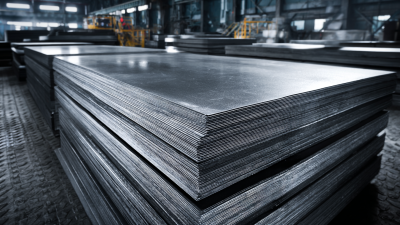

How to Choose the Best Natural Graphite Sheet for Your Applications

The selection of the optimal Natural Graphite Sheet is crucial for industries ranging from electronics to automotive applications, owing to its exceptional thermal and electrical conductivity properties. According to a recent market analysis by Global Industry Analysts, the global demand for natural graphite is projected to reach $35 billion by 2026, highlighting the material's increasing relevance in high-performance applications. This surge is largely driven by the growing need for efficient thermal management solutions in advanced technologies.

Experts in the field, such as Dr. Emily Huang, a leading researcher at the International Graphite Research Institute, emphasize the importance of choosing the right specifications for natural graphite sheets. Dr. Huang notes, "Selecting the appropriate natural graphite sheet is not just about performance; it is about ensuring reliability and longevity in critical applications." Her insight underscores the necessity of understanding the specific requirements of each project, including factors such as thickness, thermal conductivity, and integration with other materials.

As industries evolve and expand, it becomes imperative for engineers and product developers to navigate the variety of options available in the market. Understanding the properties and applications of Natural Graphite Sheets is essential to making informed decisions that maximize both performance and cost-effectiveness.

Understanding the Properties of Natural Graphite Sheets

When selecting the best natural graphite sheet for your applications, it is crucial to understand the properties that define its performance. Natural graphite sheets are prized for their excellent thermal conductivity, which can reach values up to 1500 W/mK, making them ideal for heat dissipation applications. Additionally, their natural flexibility allows them to conform to various surface geometries, enhancing their effectiveness in thermal interfaces. According to a recent industry report, the global market demand for such materials is projected to grow at a compound annual growth rate (CAGR) of 6.5%, reflecting their increasing applications in electronics and energy storage systems.

Tips for selecting the right natural graphite sheet include assessing the thickness and density tailored to your specific needs. Thicker sheets generally provide better thermal performance but may be less flexible. On the other hand, a higher density often translates to better durability and heat resistance. It’s essential to balance these characteristics based on your application requirements—whether for reliable thermal management in consumer electronics or robust thermal insulation in industrial settings.

Furthermore, consider the purity of the natural graphite sheet. High-purity graphite (99% and above) tends to offer superior thermal and electrical properties, making it suitable for high-performance applications. Always verify the product specifications against your project's requirements to ensure you choose a material that meets industry standards while providing reliability and efficiency.

Identifying Your Application Requirements for Graphite Sheets

When selecting the best natural graphite sheet for your specific applications, it is essential to first identify your application requirements. Different industries utilize graphite sheets for diverse purposes, such as thermal management, electrical conductivity, and sealing solutions. According to a recent report by Research and Markets, the global graphite market is projected to reach approximately USD 20 billion by 2025, driven largely by the increasing demand from the electronics and automotive sectors. This underscores the importance of understanding the parameters that will dictate which type of graphite sheet is best suited for your needs.

Key factors to consider include thermal conductivity, thickness, and purity levels of the graphite sheet. For instance, if your application requires efficient heat dissipation, you may want to opt for sheets with higher thermal conductivity ratings, typically measured in Watts per meter Kelvin (W/mK). Research indicates that natural graphite can achieve thermal conductivities exceeding 500 W/mK, making it ideal for high-performance applications in electronics. Additionally, purity is crucial, especially in applications that require chemical stability; sheets with less than 5% impurities are generally preferred to ensure reliability and longevity in harsh environments.

Comparing Different Types of Natural Graphite Sheets

When selecting a natural graphite sheet, it’s essential to understand the various types available and their specific applications. Natural graphite sheets can generally be categorized into flexible and rigid types.

Flexible graphite sheets are characterized by their exceptional thermal and electrical conductivity, making them ideal for applications that require high-temperature resistance and flexibility, such as gaskets and seals.

Rigid graphite sheets, on the other hand, offer superior structural integrity and are often used in applications requiring mechanical support, like thermal management systems.

Comparing these types involves examining their properties such as thickness, density, and thermal conductivity. Thicker sheets typically provide better insulation, while those with higher density may offer enhanced mechanical strength. Additionally, some natural graphite sheets are treated for specific purposes, such as improved adhesive properties or enhanced conductivity.

It’s crucial to assess the requirements of your specific application to determine which characteristics are most important. Understanding these differences will enable you to make a more informed choice tailored to your needs.

Evaluating the Quality and Purity of Graphite Sheets

When selecting a natural graphite sheet for your applications, understanding its quality and purity is crucial. Graphite sheets come in various grades, and their performance largely depends on the purity of the material used. High-purity graphite typically has fewer impurities, which can significantly enhance thermal and electrical conductivity. Therefore, examining the material’s origin and extraction process can provide insights into its quality. Look for specifications that highlight the percentage of carbon content, as this is a direct indicator of purity.

**Tips:** Always request certificates of analysis (COA) when purchasing graphite sheets. This documentation should detail the material’s composition and provide reassurance of its quality. Furthermore, consider consulting with suppliers about their grading system and any testing methodologies they use to assess the graphite's purity.

Another important factor is the density of the graphite sheet, as it also affects performance. Higher density often correlates with better mechanical strength and thermal stability. Evaluating the manufacturing process, such as whether it involves compression or layering techniques, can give additional insight into the sheet's characteristics. By carefully assessing these factors, you can ensure that the graphite sheet you choose will meet the requirements of your specific application.

**Tips:** Pay attention to customer reviews and case studies regarding the performance of graphite sheets in similar applications. This can give you practical insights into how the material behaves under real-world conditions, helping you make a more informed choice.

Tips for Sourcing and Purchasing Natural Graphite Sheets

When sourcing and purchasing natural graphite sheets, it is essential to start with a clear understanding of your application requirements. Different applications, such as thermal management, electrical conductivity, or lubrication, demand specific properties from graphite sheets. According to a recent report by the Global Graphite Market Research Institute, the demand for high-quality natural graphite has surged by over 10% annually, as industries increasingly emphasize energy efficiency and lightweight materials. This trend highlights the need for careful selection based on parameters such as thermal conductivity, compressibility, and chemical resistance.

Moreover, when sourcing natural graphite sheets, consider the supplier's reliability and the quality control processes in place. Look for manufacturers that adhere to industry standards, such as ISO certifications, as these can often be indicative of product quality. According to a survey conducted by the International Graphite Association, 67% of industry professionals cite product reliability and consistency as key factors in their purchasing decisions. Additionally, keep an eye on the sourcing of raw materials; transparency in the supply chain can significantly impact the quality of the final product, ensuring that it meets the specific needs of your applications.

How to Choose the Best Natural Graphite Sheet for Your Applications - Tips for Sourcing and Purchasing Natural Graphite Sheets

| Property | Value | Applications | Supplier Considerations |

|---|---|---|---|

| Thickness | 0.5 mm - 5 mm | Thermal insulation, Sealing | Check for certifications and material origin |

| Thermal Conductivity | 100 - 200 W/mK | Heat spreaders, Battery applications | Request test results and data sheets |

| Density | 1.5 - 2.3 g/cm³ | Electronics, Gaskets | Look for reliable suppliers with a good track record |

| Compressibility | Up to 30% | Compressible gaskets, Sealing solutions | Evaluate supplier's flexibility with custom orders |

| Temperature Resistance | -200°C to +3000°C | High-temperature applications, Aerospace | Ask about their testing procedure for high temperatures |

Related Posts

-

Maximizing Value with Best Thermal Graphite Sheets: Service Benefits and Future Repair Innovations

-

What Makes Graphite Sheets the Ideal Choice for Industrial Applications

-

Exploring Market Trends: Thermal Graphite Sheets at the 138th Canton Fair 2025 in China

-

Top 10 Graphite Natural Tips for Effective Use in Your Projects

-

7 Essential Tips for Choosing the Perfect Graphite Gasket Sheet for Your Needs

-

Unlocking Superior Performance with Best Flexible Graphite Sheets from Leading Chinese Manufacturers