How to Use Graphite Natural for Optimal Performance?

Graphite Natural has gained significant attention in various industries, primarily due to its unique properties and versatility. According to a report by the Global Graphite Market Research, the demand for natural graphite is projected to grow at a compound annual growth rate (CAGR) of 6.4% from 2021 to 2027. The increasing need for energy storage solutions and battery materials drives this growth, with graphite being a crucial component in lithium-ion batteries.

Utilizing Graphite Natural effectively requires understanding its properties. It has excellent lubricating qualities and thermal conductivity. This makes it ideal for use in industries ranging from automotive to electronics. However, not all applications achieve optimal performance. Some challenges include purity levels and sourcing sustainable materials. These issues highlight the need for careful selection and processing of Graphite Natural.

Improving the performance of Graphite Natural necessitates ongoing research and innovation. Companies must adapt to market changes and customer needs. Furthermore, manufacturers should reflect on their practices to enhance sustainability. Despite its advantages, Graphite Natural can lead to inefficiencies if not used correctly. It is crucial to explore best practices and methodologies for using Graphite Natural to maximize its benefits.

Understanding Graphite Natural and Its Properties

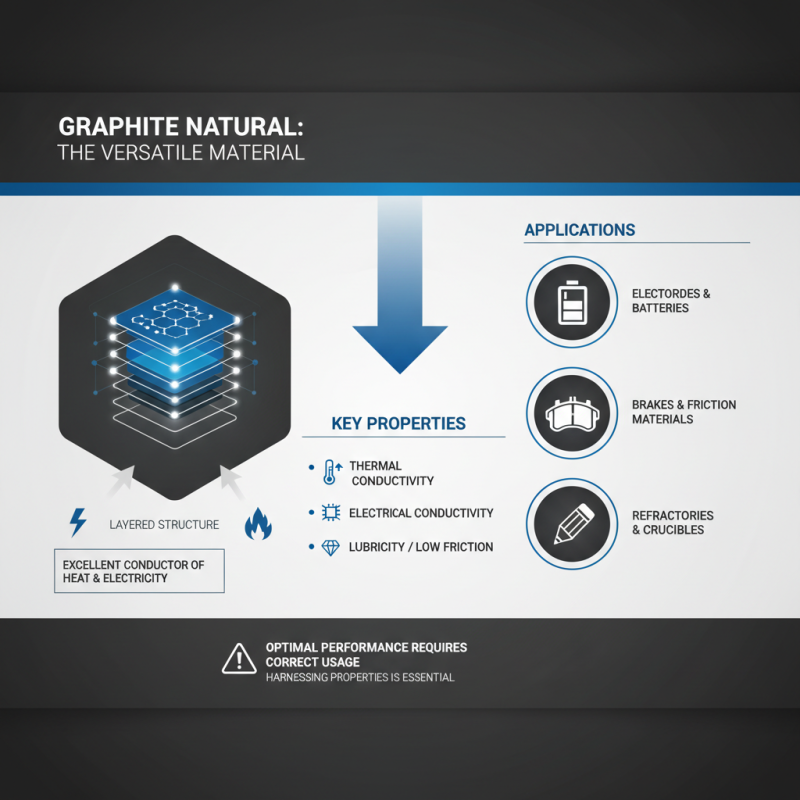

Graphite natural is a versatile material known for its unique properties. It has a layered structure, which makes it an excellent conductor of heat and electricity. This property allows it to perform well in a variety of applications. However, its effectiveness can diminish if not used correctly. Understanding how to harness these properties is essential for optimal performance.

Tips: Always ensure that the graphite is of high quality. Impurities can reduce effectiveness. It's wise to test your source before large-scale use.

Graphite natural's lubricating abilities make it useful in machinery and equipment. It helps reduce friction and wear. However, over-application can lead to buildup and unwanted residue. Balancing the amount is crucial. Adjust your application based on your specific needs. Remember, less can sometimes be more.

Tips: Keep surfaces clean to avoid contamination. Regular maintenance checks can prevent issues. Being mindful of how much you use can save time and resources in the long run.

Identifying Applications of Graphite Natural in Various Industries

Natural graphite is increasingly vital across various industries. Its unique properties make it suitable for multiple applications. For instance, in the battery industry, natural graphite is the primary material for anodes in lithium-ion batteries. Reports indicate the demand for these batteries is expected to reach 10 million tons by 2025, driven by electric vehicle growth.

The steel industry also relies heavily on natural graphite. It is used as a lubricant in the production process. The global demand for graphite in this sector is forecasted to grow at a CAGR of 4.5% from 2021 to 2028. However, the environmental impact of mining and processing graphite requires careful consideration. Sustainable practices must be prioritized to minimize harm.

Tips: Always assess the suitability of natural graphite for your specific application. Test different grades to identify the best fit. Consider how extraction methods might impact your supply chain. Remember, the future of graphite depends on innovation and sustainability. Look for ways to improve processes without sacrificing quality.

Preparation and Processing Techniques for Optimal Performance

Preparation and processing techniques are crucial when using graphite natural to achieve optimal performance. Start by selecting high-quality raw graphite. Purity and structure impact the final product. Ensure the graphite is properly crushed to the desired particle size. This step can affect the reactivity and performance in applications.

Mixing the graphite with other materials can enhance its properties. Experiment with ratios to find the best combination. A homogeneous blend is essential. Avoid clumping, as it can lead to uneven performance. In the processing phase, consider heat treatment. This can alter the structure for improved effectiveness. However, excessive heat may degrade the material, so monitor temperatures closely.

During application, observe how the graphite performs. Are there inconsistencies? Evaluate if the preparation steps align with the results you see. Adjust the techniques based on practical outcomes. Sometimes, what seems ideal in theory may not yield the same in reality. Keeping a flexible approach will lead to better optimization over time.

Performance Analysis of Graphite Natural Processing Techniques

Best Practices for Handling and Storing Graphite Natural

Handling and storing natural graphite requires careful attention. Proper storage conditions are crucial for maintaining its quality. Keep it in a cool, dry place. Humidity can compromise its properties. Use airtight containers to avoid exposure to moisture. It's tempting to leave materials out for easy access, but this can lead to degradation.

When transporting graphite, use padding to prevent damage. If the graphite is in powder form, avoid shaking the container too much. Even minor impacts can lead to clumping. Watch for any signs of contamination. Graphite can attract dust and dirt, so cleanliness is key. It’s easy to overlook though, which can impact performance.

Regularly check on your supply. Make adjustments based on how you use it. For instance, smaller amounts may suffice for lighter projects. Larger projects may require more frequent restocking. Staying organized can be a challenge. Yet, it is a vital part of effective graphite use.

Evaluating Performance Metrics and Benefits of Graphite Natural Usage

When evaluating the performance metrics of Graphite Natural, it’s critical to consider multiple aspects. Studies indicate that Graphite Natural can enhance thermal conductivity by up to 30%. This significant improvement can lead to better energy efficiency. Using Graphite Natural can also reduce friction in various applications, resulting in lower wear and tear on machinery.

Data from industry reports show that companies utilizing Graphite Natural experience a 15-20% reduction in operating costs over time. However, it is essential to note that these benefits may not be universally applicable. Some users report challenges with consistency in performance. Variations in material quality can impact the expected results.

Overall, while the potential advantages of Graphite Natural are substantial, users must proceed cautiously. Regular evaluations and adjustments might be necessary to achieve optimal outcomes. Ultimately, understanding the unique properties of Graphite Natural allows for better integration into various applications.

How to Use Graphite Natural for Optimal Performance? - Evaluating Performance Metrics and Benefits of Graphite Natural Usage

| Performance Metric | Value | Benefits of Graphite Natural Usage |

|---|---|---|

| Thermal Conductivity | 150 - 200 W/m·K | Improves heat dissipation in industrial applications. |

| Density | 1.8 - 2.3 g/cm³ | Provides lightweight solutions without sacrificing strength. |

| Compressibility | 0.02 - 0.05 cc/g | Ensures minimal volume change under pressure, enhancing component longevity. |

| Chemical Resistance | Highly resistant | Suitable for harsh environments; prolongs equipment lifespan. |

| Electrical Conductivity | 10^6 S/m | Ideal for electronic and electrical applications. |

Related Posts

-

Unmatched Quality and Reliability in Best Graphite Natural Products from Trusted Chinese Manufacturers

-

Exploring the Benefits of Best Graphite Natural Over Conventional Alternatives

-

The Ultimate Guide to Sourcing the Best Natural Graphite: Insights and Trends for Global Buyers

-

Top 10 Graphite Natural Tips for Effective Use in Your Projects

-

How to Use Graphite Natural for Optimal Performance in Your Projects

-

Mastering Graphite Thermal Film Application in Your Projects a Step by Step Guide