Unlocking the Potential of Thermal Graphite Sheets: The Future of Efficient Heat Management

As industries increasingly prioritize effective heat management solutions, Thermal Graphite Sheets have emerged as a pivotal technology in enhancing thermal conductivity and dissipation. According to a report by Market Research Future, the global thermal management materials market is projected to reach USD 20 billion by 2026, with a compound annual growth rate (CAGR) of 5.7%. This growth is driven by the expanding demand for efficient cooling systems in electronics, automotive, and renewable energy sectors. Thermal Graphite Sheets, known for their exceptional heat conductivity, lightweight and flexible properties, offer a promising alternative to traditional thermal interface materials. Their unique structure allows for efficient heat spreading, ensuring optimal performance and reliability in high-performance applications. As we delve into the potential of Thermal Graphite Sheets, we will explore how they can redefine heat management paradigms across various industries, paving the way for innovative solutions and greater energy efficiency.

Exploring the Unique Properties of Thermal Graphite Sheets for Heat Management

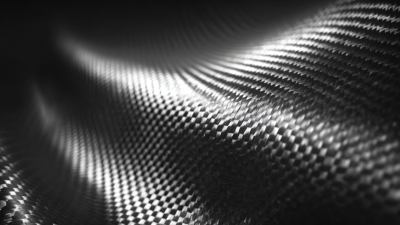

Thermal graphite sheets are emerging as a revolutionary solution for effective heat management across various industries, particularly in electronics and energy sectors. These sheets are characterized by their exceptional thermal conductivity, which can reach up to 1500 W/m·K, significantly outperforming traditional materials like metals and ceramics. This property enables them to efficiently dissipate heat from critical components, reducing the risk of overheating and boosting the performance of devices. According to a report by Research and Markets, the global thermal management market is projected to grow at a CAGR of 9.2% from 2021 to 2026, highlighting the increasing demand for efficient heat management solutions.

Furthermore, the lightweight and flexible nature of thermal graphite sheets make them ideal for applications where space and weight constraints are critical. Unlike bulky metal heat sinks, these sheets can be easily integrated into slim and compact designs without compromising performance. A study by IDTechEx predicts that the demand for advanced thermal materials, including graphite sheets, will reach $4 billion by 2030, driven by the rise of electric vehicles and high-performance computing. These unique properties not only enhance device efficiency but also contribute to the overall sustainability of manufacturing processes, as they can be produced using eco-friendly methods.

Unlocking the Potential of Thermal Graphite Sheets for Heat Management

This chart illustrates the thermal conductivity of various materials used in heat management applications, showcasing the superior performance of thermal graphite sheets compared to traditional materials.

Innovative Applications of Thermal Graphite Sheets in Electronics and Beyond

Thermal graphite sheets are emerging as a critical material in the ongoing evolution of heat management solutions across various industries. With their exceptional thermal conductivity and flexibility, these sheets are ideally suited for applications in electronics, where efficient heat dissipation is paramount. The increasing complexity and miniaturization of electronic devices demand advanced thermal interface materials that can effectively manage the heat generated by high-performance components. As a result, industries are increasingly turning to thermal graphite sheets to enhance the performance and reliability of their products.

Beyond electronics, the potential applications of thermal graphite sheets are vast and varied. Industries such as automotive, renewable energy, and aerospace are exploring their use for thermal management systems. The growing focus on energy efficiency and sustainability is likely to drive the adoption of these innovative materials. With the flexible graphite market projected to grow substantially in the coming years, the demand for high-performance thermal management solutions, including thermal graphite sheets, presents significant opportunities for development and innovation across multiple sectors.

Comparative Analysis: Thermal Graphite Sheets vs. Traditional Heat Management Solutions

In the realm of heat management solutions, thermal graphite sheets have emerged as a game-changer compared to traditional materials. Unlike conventional methods that often rely on bulky metal plates or thermal pads, thermal graphite sheets are remarkably thin and lightweight, offering enhanced thermal conductivity. This characteristic allows for more efficient heat dissipation in compact electronic devices, which is crucial as industries strive for slimmer designs without compromising performance.

Moreover, thermal graphite sheets boast superior flexibility and conformability, enabling them to fit seamlessly into various applications. Traditional heat management solutions may require complex assembly processes, increasing production time and costs. In contrast, thermal graphite sheets simplify installation, leading to more streamlined manufacturing workflows. Additionally, their high thermal performance can help extend the lifespan of electronic components by preventing overheating, which is a common issue faced with traditional solutions. As technology continues to advance, the adoption of thermal graphite sheets will likely play a pivotal role in optimizing thermal management strategies across multiple sectors.

Future Trends: The Evolution of Thermal Graphite Sheet Technology

The evolution of thermal graphite sheet technology is poised to redefine thermal management solutions across various industries. As electronic devices become more powerful and compact, the demand for efficient heat dissipation materials is escalating. Future trends indicate that thermal interface materials (TIMs) will integrate advanced properties to enhance thermal conductivity and stability, catering to the unique needs of emerging technologies such as 5G and electric vehicle power electronics. Research into high thermal conductivity polymer composites and innovative manufacturing processes like 3D printing is likely to play a crucial role in the development of next-generation thermal graphite sheets.

Moreover, as sustainability becomes a focal point in energy storage and management technologies, thermal graphite sheets are positioned to offer eco-friendly advantages. Insights into energy-efficient materials will not only address performance challenges but also contribute to the decarbonization of global energy systems. The interplay between thermal management technologies and evolving market dynamics suggests a vibrant future for thermal graphite sheets, enhancing the overall efficiency and longevity of electronic devices while promoting sustainable practices across multiple sectors.

Sustainability and Efficiency: The Environmental Impact of Thermal Graphite Sheet Usage

The usage of thermal graphite sheets offers a sustainable solution for efficient heat management across various industries. These sheets not only excel in thermal conductivity but are also produced from natural flake graphite, which minimizes the carbon footprint associated with their manufacturing. By replacing traditional cooling methods that often rely on heavy metals and complex processing, thermal graphite sheets contribute to environmental conservation. Their lightweight design further reduces energy consumption, as less energy is required for transportation and installation in electronic devices.

Moreover, the longevity of thermal graphite sheets enhances their eco-friendliness. Unlike many conventional cooling solutions that require frequent replacements, these sheets can endure extreme temperatures while maintaining performance, resulting in lower waste generation over time. As industries increasingly shift towards sustainable practices, the integration of thermal graphite sheets paves the way for greener and more efficient technologies. Their direct impact on reducing energy consumption and enhancing product lifespan emphasizes their role in transforming heat management solutions into environmentally responsible choices.

Unlocking the Potential of Thermal Graphite Sheets: The Future of Efficient Heat Management - Sustainability and Efficiency: The Environmental Impact of Thermal Graphite Sheet Usage

| Property | Value | Importance |

|---|---|---|

| Thermal Conductivity | 1500 W/m·K | High efficiency in heat dissipation |

| Density | 1.8 g/cm³ | Lightweight and suitable for various applications |

| Operating Temperature Range | -200°C to 3000°C | Versatile for extreme conditions |

| Eco-friendliness | Yes | Sustainable material choice |

| Recyclability | Yes | Contributes to waste reduction |

| Industry Applications | Electronics, automotive, aerospace | Used in critical heat management systems |

Related Posts

-

Understanding Industry Standards and Reasons Behind the Best Graphite Thermal Sheet Selection

-

Top 10 Thermal Graphite Sheet Manufacturers from China at the 137th Canton Fair

-

China's Leading Edge: The Evolution of the Best Graphite Thermal Sheets in Global Manufacturing

-

Exploring the Future: Advances in Graphite Thermal Film Technology by 2025

-

Leading Graphite Sheet Manufacturer in China Delivering Export Quality to the Global Market

-

Exploring the Versatility of the Best Graphite Sheet: Unique Use Cases and Applications