Leading Graphite Sheet Manufacturer in China Delivering Export Quality to the Global Market

In the rapidly evolving materials industry, the demand for high-performance solutions such as graphite sheets is on the rise, driven by sectors including electronics, automotive, and energy. According to a recent market study from Grand View Research, the global graphite sheet market is projected to surpass USD 1.5 billion by 2025, with significant growth attributed to the increasing adoption of thermal management applications. As businesses seek reliable suppliers to meet this demand, finding a manufacturer that offers export quality graphite sheets is paramount. With China's dominance in the graphite production sector, companies worldwide are presented with a unique opportunity to source top-tier materials. This blog aims to guide you through the essentials of identifying high-quality suppliers in China, ensuring you invest in products that not only meet but exceed your performance expectations.

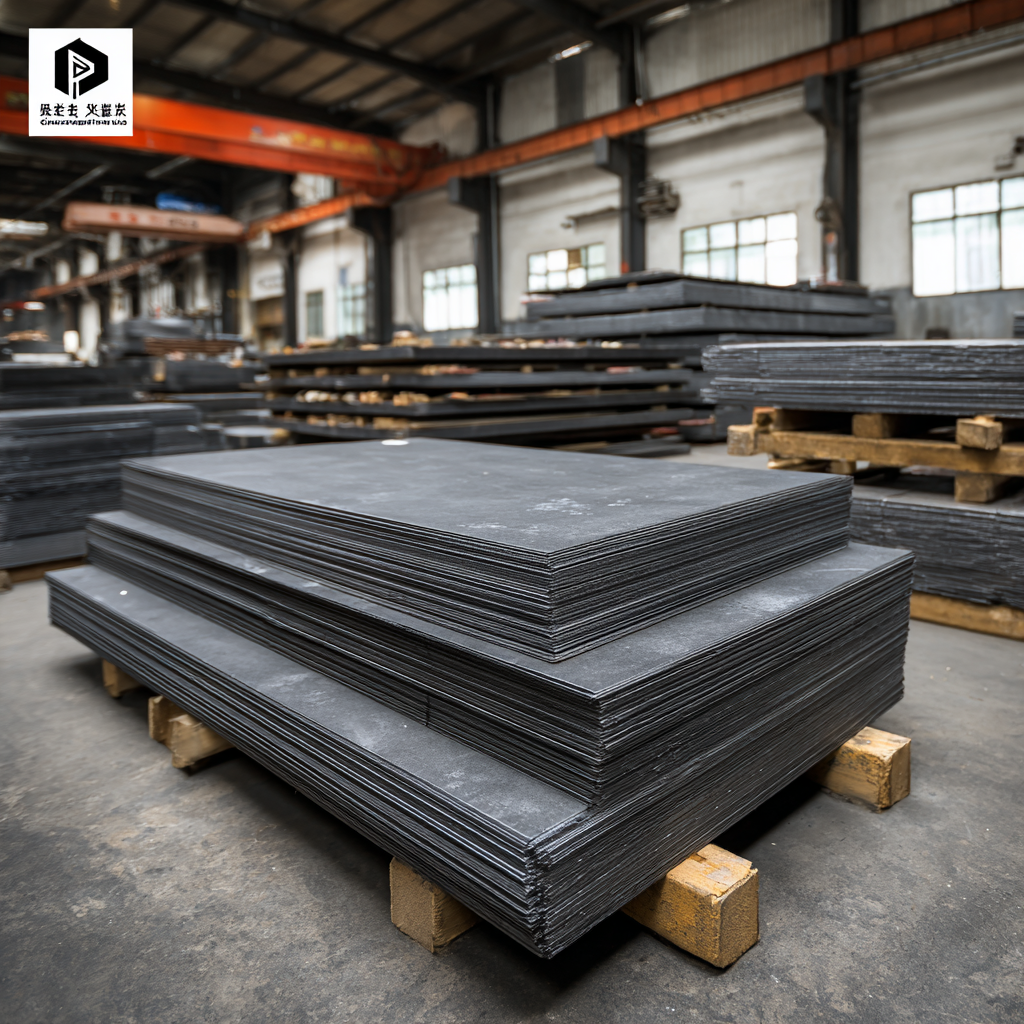

Overview of Graphite Sheet Manufacturing in China

China has established itself as a formidable player in the graphite sheet manufacturing industry, catering to the growing global demand for high-quality graphite products. The country's extensive natural graphite reserves, combined with advanced production technologies, enable manufacturers to produce sheets that meet international quality standards. These sheets are essential in various applications, including electronics, automotive, and energy sectors, where thermal management and conductivity are crucial.

The manufacturing process in China involves several stages, from sourcing raw materials to cutting-edge machining techniques. Chinese manufacturers have adopted modern technologies and innovative approaches to enhance the performance and durability of graphite sheets. Rigorous quality control measures are in place to ensure that the final products are reliable and efficient for their intended uses. As a result, Chinese graphite sheet manufacturers are gaining recognition in the international market, providing export-quality products that help meet the diverse needs of industries around the world.

Key Features of Export-Quality Graphite Sheets

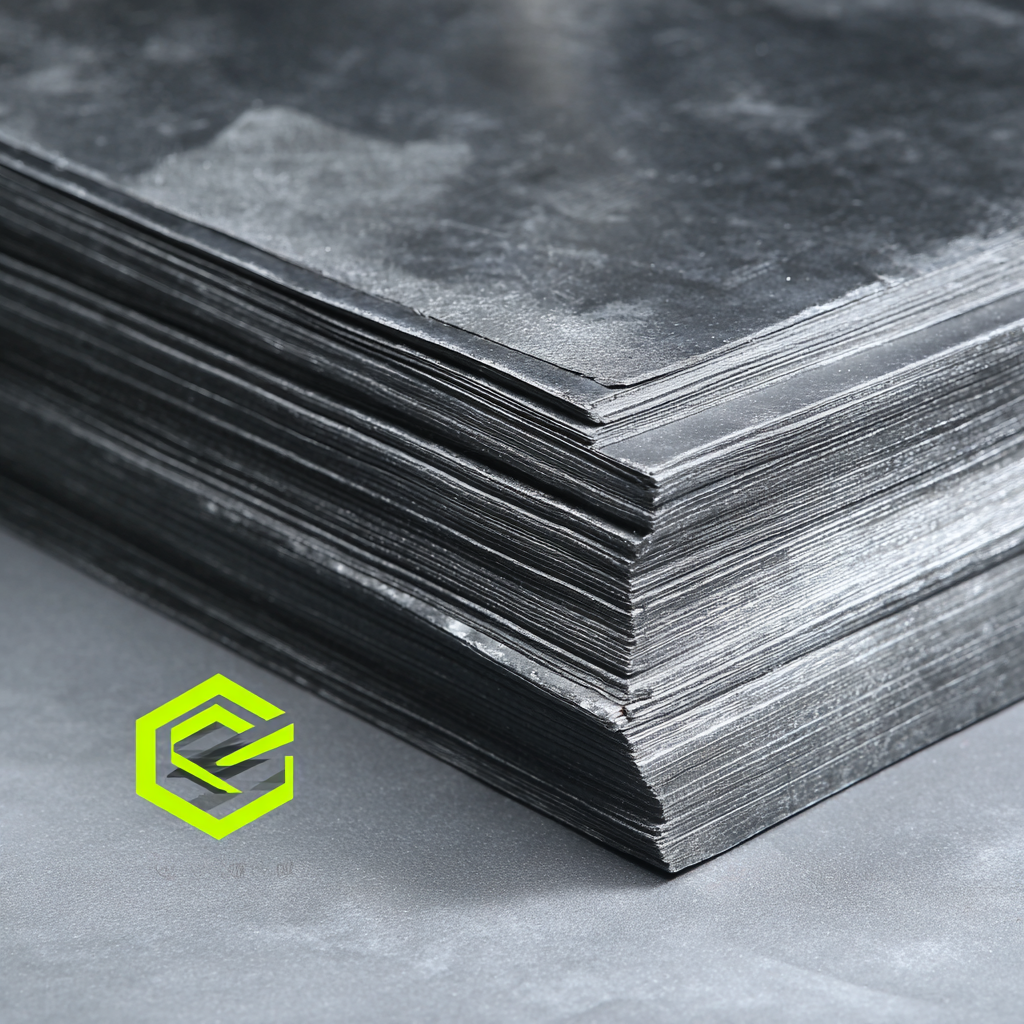

Graphite sheets have gained significant attention in various industries due to their exceptional thermal and electrical conductivity. A leading graphite sheet manufacturer in China is setting the benchmark by offering export-quality products that meet stringent international standards. These sheets are known for their high purity levels, which enhance their performance in critical applications, including electronics, aerospace, and automotive sectors. Their ability to withstand high temperatures and resist corrosion makes them a preferred choice for demanding environments.

One of the key features of export-quality graphite sheets is their versatility in design and application. Manufacturers utilize advanced production techniques to create sheets that can be tailored to specific dimensions and thicknesses, ensuring compatibility with various equipment. Additionally, these sheets come with excellent flexibility, allowing for easy installation and integration. The refined surface finish ensures minimal friction in dynamic applications, while the uniform density across the sheet enhances stability and reliability.

Furthermore, export-quality graphite sheets possess outstanding mechanical strength, making them durable and long-lasting. Their resistance to oxidation and thermal fatigue makes them ideal for high-performance applications that require longevity. As industries continue to evolve, the emphasis on quality and reliability in graphite sheet production cannot be overstated, positioning these products as essential components in modern technological advancements.

Applications of Graphite Sheets in Various Industries

Graphite sheets have found extensive applications across various industries due to their unique properties, including thermal conductivity, flexibility, and chemical resistance. These sheets are widely utilized in the electronics industry, serving as thermal interface materials and heat sinks that enhance device performance and durability. In the automotive sector, graphite sheets contribute to the efficiency of electric vehicles by providing vital thermal management solutions, ensuring better energy performance and safety.

Moreover, the synthesis of graphite from biomass is emerging as a sustainable alternative, opening new avenues for eco-friendly production methods. This innovation not only addresses environmental concerns but also positions graphite as a key player in the renewable energy space. With the burgeoning flexible graphite market projected to reach USD 0.45 billion by 2030, the potential for graphite sheets in diverse applications continues to expand. The integration of advanced materials like graphene oxide with traditional graphite sheets further enhances their utility in areas such as pollution control and energy storage, showcasing the versatility and importance of graphite in modern industry.

Applications of Graphite Sheets in Various Industries

Quality Control Measures in Graphite Sheet Production

In the competitive landscape of graphite sheet manufacturing, quality control measures are paramount to ensuring the delivery of export-quality products that meet the rigorous demands of the global market. Advanced production techniques now incorporate scalable aqueous-based supercapacitors which utilize a hydrophobic anti-corrosion graphite passivation layer. This innovation highlights the dual focus on performance and safety, reinforcing the industry's commitment to superior quality standards.

Furthermore, recent advancements in the examination of graphite composites, using X-Ray computer tomography, have shed light on the imperfections within bipolar plates. Such insights are critical for improving the manufacturing process and achieving high-quality outputs. Playing a crucial role in this journey is the synthesis of graphene materials through eco-friendly methods like electrochemical exfoliation, which not only enhances product quality but also aligns with environmental considerations. As Chinese manufacturers continue to develop ultra-high pure graphite, the emphasis on stringent quality control measures is undeniable, positioning them as leaders in the global market.

Leading Graphite Sheet Manufacturer in China Delivering Export Quality to the Global Market - Quality Control Measures in Graphite Sheet Production

| Quality Control Measures | Description | Frequency | Responsible Team |

|---|---|---|---|

| Raw Material Inspection | Verification of graphite material properties before production. | Every Batch | Quality Assurance Team |

| Process Control | Monitoring temperature and pressure during manufacturing. | Continuous | Production Team |

| Post-Production Testing | Physical and chemical testing of finished graphite sheets. | Each Batch | Testing Laboratory |

| Customer Feedback Analysis | Gathering and analyzing feedback to improve quality. | Quarterly | Customer Service Team |

| Compliance Audits | Ensuring adherence to international quality standards. | Annually | Compliance Team |

Future Trends in the Global Graphite Market

The graphite market is poised for transformative growth as industries demand higher performance materials that can withstand extreme conditions. With the rise of electric vehicles and renewable energy technologies, the need for high-quality graphite sheets is becoming increasingly critical. These sheets not only serve as essential components in batteries and thermal management systems but also offer advantages in lightweight and efficient designs. As a leading graphite sheet manufacturer in China, our commitment to quality and innovation positions us to meet global demands while adhering to strict industry standards.

Future trends indicate a shift towards sustainable practices in the graphite production process. Companies are exploring eco-friendly extraction methods and recycling initiatives to minimize environmental impacts. Additionally, advancements in technology are paving the way for enhanced graphite performance, including improved conductivity and thermal resistance.

As the global market continues to evolve, manufacturers must adapt and invest in research and development to maintain a competitive edge. Embracing these trends will not only benefit the industry but also contribute to a greener and more sustainable future for all.