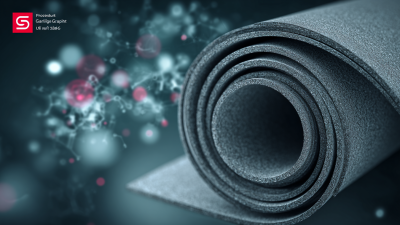

Innovative Applications of Flexible Graphite Sheet in High Performance Industries

The demand for advanced materials in high-performance industries has led to a surge in the adoption of innovative solutions like Flexible Graphite Sheet. According to industry reports, the market for graphite materials is projected to grow at a CAGR of 4.5% between 2022 and 2030, driven by their exceptional thermal conductivity, chemical resistance, and mechanical strength.

Flexible Graphite Sheets have emerged as vital components in various applications, such as thermal management in electronics, sealing solutions in automotive engines, and flexible energy storage systems. As industries increasingly focus on efficiency and sustainability, the versatility of Flexible Graphite Sheet makes it an attractive option for addressing modern engineering challenges.

This blog will explore the multifaceted applications of Flexible Graphite Sheet across different sectors, highlighting its role in enhancing performance and sustainability.

Innovative Uses of Flexible Graphite Sheet in Aerospace Engineering

The aerospace industry is increasingly harnessing the unique properties of

flexible graphite sheets to enhance performance and efficiency. Flexible graphite serves as an

essential material, offering exceptional thermal and mechanical resilience that is

crucial for aerospace applications. Its lightweight nature combined with remarkable conductivity makes it ideal for components that require

effective heat management and durability under extreme conditions. One prominent application is in thermal de-icing systems,

where flexible graphene films are utilized to maintain optimal temperatures on aircraft surfaces, thereby improving safety and operational reliability.

Tip: When considering the application of flexible graphite in aerospace,

it's important to assess the specific performance requirements of each component. This includes evaluating thermal conductivity,

weight limitations, and compatibility with other materials used in aerospace manufacturing.

Moreover, the integration of flexible graphite sheets in advanced manufacturing processes such as 3D printing is revolutionizing

the industry. By enabling the production of complex geometries and lightweight structures with enhanced properties, flexible graphite plays a pivotal role in

the development of next-generation aircraft. As the need for innovation in aerospace engineering grows, so does the exploration of flexible graphite's capabilities

in creating efficient, high-performance solutions.

Tip: For aerospace engineers, it's vital to stay updated on advancements in composite materials

and their applications. Engaging with ongoing research and exploring industry case studies can provide valuable insights into maximizing the benefits of

flexible graphite in design and production processes.

Advanced Thermal Management Solutions with Flexible Graphite Sheets

Flexible graphite sheets are revolutionizing thermal management solutions across various high-performance industries. Their unique properties, including excellent thermal conductivity and lightweight characteristics, make them ideal for applications that require efficient heat dissipation. In the automotive sector, for instance, manufacturers are increasingly turning to these sheets for their engine components and battery systems to enhance thermal regulation, improve efficiency, and prolong the lifespan of critical parts.

Moreover, in the electronics industry, the demand for advanced cooling solutions has skyrocketed with the advancement of compact, high-performance devices. Flexible graphite sheets provide an effective solution by enabling rapid heat spread and minimizing hot spots, ensuring that devices operate within their optimal temperature ranges. This not only enhances performance but also improves reliability, giving manufacturers a competitive edge in a rapidly evolving market.

As industries continue to innovate, the applications of flexible graphite sheets in thermal management will undoubtedly expand, offering even more efficient solutions for the challenges of modern engineering.

Flexible Graphite Sheets in Renewable Energy Applications

Flexible graphite sheets are making waves in renewable energy applications, providing innovative solutions for a variety of energy-related challenges. One of the most promising developments is the use of expanded graphite and reduced graphene oxide composites, which effectively enhance the efficiency of solar-driven technologies. These materials not only improve thermal management but also contribute to the sustainability of energy production processes.

Tips for enhancing performance: When integrating flexible graphite sheets into renewable energy systems, focus on optimizing their thermal conductivity properties. Utilizing a one-step thermal process for functionalization can yield superior performance by enhancing the interaction between graphite and active materials. Additionally, exploring the use of kish-expanded graphite through space-confined intercalation expansion can lead to rapid production methods suitable for applications in aluminum-ion batteries.

Moreover, as the need for advanced energy storage solutions grows, utilizing flexible graphite for the development of stretchable supercapacitors presents an exciting avenue for innovation. This approach can bridge the gap between advancements in flexible technologies and energy storage capacities. Consider conducting studies on the synergistic effects of alloy coatings on graphite to maximize the potential of these materials in practical applications.

Revolutionizing Automotive Cooling Systems with Flexible Graphite

The integration of flexible graphite sheets in automotive cooling systems is creating significant advancements in thermal management. With the exceptional thermal diffusivity of high-performance graphite, vehicles are able to dissipate heat 2.6 times faster than traditional materials like copper. This rapid heat dissipation is essential for maintaining optimal motor efficiency, particularly in high-performance applications such as AI and HPC. As automotive manufacturers strive for better energy efficiency and performance, the adoption of flexible graphite is proving to be a revolutionary step forward.

To further enhance cooling systems, phase change materials (PCMs) can be incorporated into the design. These innovative materials absorb and release thermal energy during phase transitions, effectively regulating temperatures within the vehicle. By utilizing PCMs alongside flexible graphite sheets, automotive engineers can create a highly efficient thermal management system that not only improves engine performance but also extends the longevity of vehicle components.

Tips: When designing cooling systems, consider using a combination of flexible graphite and PCMs for optimal thermal regulation. Regular maintenance checks to ensure the integrity of these materials can help prevent overheating and enhance overall vehicle performance. Exploring advanced materials can lead to groundbreaking solutions that meet the challenges of modern automotive engineering.

Innovative Applications of Flexible Graphite Sheet in High Performance Industries - Revolutionizing Automotive Cooling Systems with Flexible Graphite

| Application Area | Material Characteristics | Benefits | Typical Use Cases |

|---|---|---|---|

| Automotive Cooling Systems | High thermal conductivity, flexible, lightweight | Improved heat dissipation, reduced weight | Radiators, heat exchangers |

| Electronics Cooling | High thermal stability, excellent electrical insulation | Enhanced performance, longevity of components | Power electronics, circuit boards |

| Aerospace Applications | Lightweight, high resistance to thermal shock | Weight savings, reliable thermal management | Jet engine components, spacecraft |

| Industrial Machinery | Chemically resistant, durable | Reduced maintenance costs, extended equipment life | Heat exchangers, boilers |

High-Performance Electronics: The Role of Flexible Graphite Sheets

Flexible graphite sheets have emerged as a crucial component in the high-performance electronics sector, demonstrating remarkable properties that cater to the evolving demands of modern technology. These sheets are not only compressible and porous but also exhibit excellent electrical and thermal conductivity, making them ideal for applications in devices such as sensors and antennas. As the flexible graphite market is projected to reach USD 0.45 billion by 2030, innovations in material applications will likely drive significant advancements in electronic device performance.

One of the most exciting developments is the integration of flexible graphite in ultra-low-cost pressure sensors designed for artificial intelligence-enhanced e-skin applications. By utilizing a water-soluble graphite functional layer, these sensors provide unprecedented sensitivity and flexibility, paving the way for more advanced robotic functionalities. Additionally, the high conductivity of flexible graphite films simplifies the design of radio-frequency antennas, addressing the barriers faced in contemporary electronics. This synergy between the material’s properties and innovative engineering continues to expand the horizons of high-performance electronics, offering a glimpse into the future of flexible technologies.

Innovative Applications of Flexible Graphite Sheets in High-Performance Electronics

Related Posts

-

Unlocking Superior Performance with Best Flexible Graphite Sheets from Leading Chinese Manufacturers

-

Exploring Future Innovations in Best Flexible Graphite Gasket Technology for 2025

-

Challenges Faced by Industries When Using Flexible Graphite Sheets

-

Exploring Unique Alternatives to Best Graphite Paper Staples for Your Crafting Needs

-

Unmatched Quality and Reliability in Best Graphite Natural Products from Trusted Chinese Manufacturers

-

What Makes Graphite Sheets the Ideal Choice for Industrial Applications