What is Graphite Lining Paper and How is it Used?

Graphite Lining Paper is a specialized material used in various industries. It plays an essential role in applications requiring durability and performance. As James A. Wright, an industry expert, notes, "Graphite Lining Paper is crucial for enhancing the lifespan of equipment." This quote highlights its significance.

The unique properties of Graphite Lining Paper allow it to resist wear and tear in high-friction environments. Its properties include excellent thermal resistance, making it suitable for demanding applications. For instance, manufacturers often utilize it in the production of seals and gaskets.

However, some challenges come with its use. Sourcing quality Graphite Lining Paper can be difficult. The production process can vary widely, leading to inconsistencies in performance. Users may find it frustrating when the material does not meet expectations. Thus, understanding the specifications of Graphite Lining Paper is vital for ensuring long-lasting results.

What is Graphite Lining Paper?

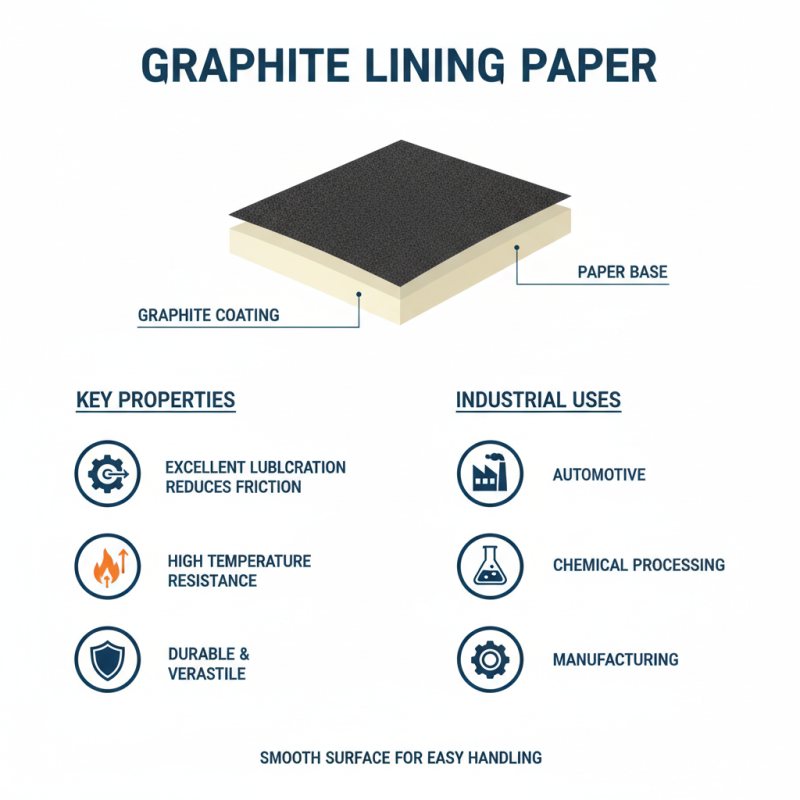

Graphite lining paper is a specialized material used in various industrial applications. It consists of a paper base coated with graphite. This coating provides excellent lubrication properties, making it ideal for reducing friction in numerous settings. Its smooth surface allows for easy handling and can withstand high temperatures. Many industries value its durability and versatility.

When using graphite lining paper, it's essential to consider the application area. Ensure the surface is clean and dry before application. This will maximize adhesion and effectiveness. It can be tricky to apply evenly, so practice makes perfect.

Tip: Always use the right tools for a clean application. A straight edge can help you cut it to size without excess waste.

In settings like machinery, graphite lining paper can protect components from wear. However, improper use may lead to inadequate protection. If the layers are too thick, it might not adhere properly. Experimenting with thickness is crucial.

Tip: Test on a small section before full application. This way, you can see how it performs in your specific environment.

Properties and Characteristics of Graphite Lining Paper

Graphite lining paper is a unique material known for its versatile properties. It is primarily composed of graphite, giving it distinct characteristics. The paper is lightweight yet durable. This combination makes it suitable for various applications. It can withstand high temperatures and pressure. Many industries benefit from its features.

One key characteristic is its low friction surface. This property reduces wear in mechanical applications. Users often appreciate the paper’s ability to provide a smooth finish. It also has excellent electrical conductivity, which is valuable in electronic applications. The paper can be easily cut and shaped to fit specific needs. However, some may find it challenging to work with due to its delicate nature.

Another important aspect is the paper's resistance to chemicals. It can endure exposure to solvents and acids without degradation. This resilience makes it ideal for use in harsh environments. Despite its advantages, certain applications may require careful handling. The balance between fragility and functionality can be tricky. Users must weigh these factors when selecting graphite lining paper for their projects.

What is Graphite Lining Paper and How is it Used? - Properties and Characteristics of Graphite Lining Paper

| Property | Description |

|---|---|

| Material Composition | Made primarily from natural graphite and resin |

| Thickness | Typically ranges from 0.5 mm to 2.0 mm |

| Heat Resistance | Can withstand temperatures up to 2000°C |

| Electrical Conductivity | Excellent electrical conductor |

| Moisture Resistance | Highly resistant to moisture and corrosion |

| Applications | Used in industrial machinery, electrical insulation, and heat shields |

| Advantages | Durability, high thermal conductivity, and chemical resistance |

Applications of Graphite Lining Paper in Various Industries

Graphite lining paper serves diverse purposes across various industries. In manufacturing, it provides a protective layer for components. This is crucial in sectors where friction reduction is necessary. According to a recent industry report, the use of graphite lining paper can improve machinery efficiency by up to 15%. This reduction can lead to significant cost savings over time.

In the automotive industry, graphite lining paper helps in the production of multiple parts. It enhances wear resistance and extends the lifespan of critical components. Research indicates that vehicles can experience a 20% decrease in maintenance costs when graphite lining materials are employed. This advantage is especially valuable as the industry shifts towards more sustainable practices.

The aerospace sector also benefits from graphite lining paper. Its lightweight and robust qualities make it ideal for high-demand applications. A study revealed that using graphite lining can reduce overall weight in aerospace components by as much as 10%. However, challenges exist regarding the uniformity of application. Ensuring consistent quality can be difficult, and manufacturers must find ways to address this issue.

Benefits of Using Graphite Lining Paper for Manufacturing Processes

Graphite lining paper is increasingly recognized in various manufacturing processes. This material provides a unique solution due to its excellent properties. It can withstand high temperatures and offers great wear resistance. The resilience of graphite lining makes it suitable for diverse applications. It reduces friction, which can lead to improved efficiency in machinery.

Using graphite lining paper also enhances product longevity. The protective layer helps to minimize damage from abrasion and chemical exposure. As a result, manufacturers often find a reduction in maintenance costs. This can lead to less downtime, which is a significant advantage. However, some may overlook the importance of proper application techniques. Inconsistent results can happen if the lining is not installed correctly.

Another important benefit is the versatility of graphite lining paper. It can be used in many industries, including automotive and aerospace. Despite its advantages, manufacturers need to be aware of potential challenges. Proper storage and handling are critical to maintaining its performance. If not stored correctly, the material may degrade. This could lead to increased waste and inefficiency in production.

Benefits of Using Graphite Lining Paper in Manufacturing Processes

This chart illustrates the various benefits of using Graphite Lining Paper in manufacturing processes, rated on a scale of 1 to 10. The ratings reflect key attributes such as heat resistance, durability, chemical resistance, cost-effectiveness, and ease of use.

Comparison of Graphite Lining Paper with Other Lining Materials

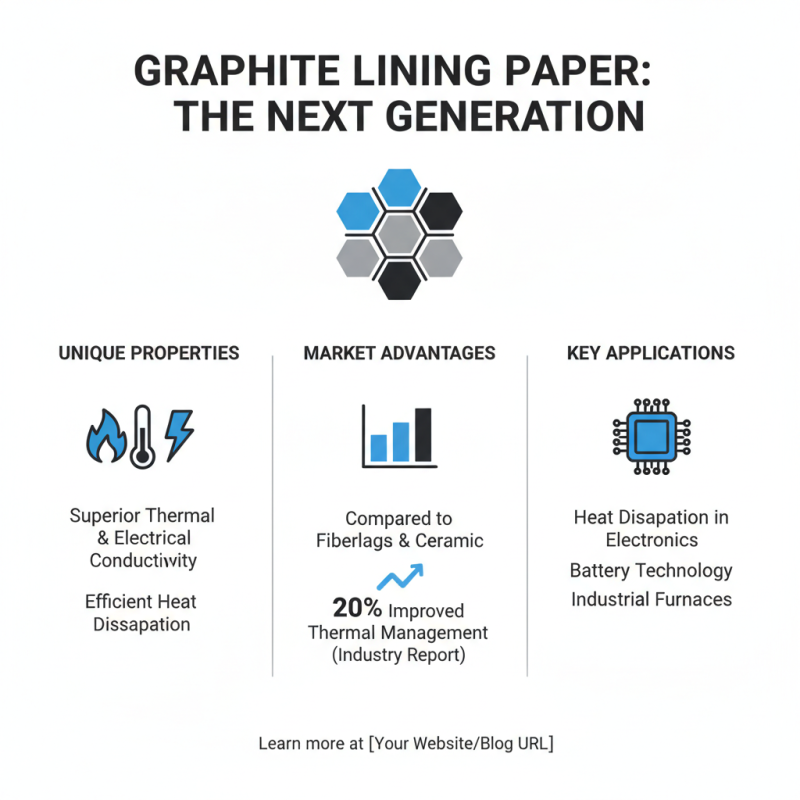

Graphite lining paper has gained attention for its unique properties in the lining materials market. Compared to traditional materials like fiberglass and ceramic, graphite lining paper offers superior thermal and electrical conductivity. This makes it useful in applications requiring efficient heat dissipation. According to a recent industry report, graphite linings have shown a 20% improvement in thermal management compared to fiberglass alternatives.

However, the choice of lining material often comes down to specific needs. Fiberglass is lighter and easier to handle, making it preferable in some industries. Ceramic, on the other hand, provides excellent corrosion resistance. Yet, its brittle nature can lead to challenges in handling. Interestingly, just 30% of facilities have fully adopted graphite lining, indicating a gap in awareness or capability. This raises questions about why more industries have not transitioned to using graphite lining paper.

In practical application, graphite lining paper is often preferred in environments where high temperatures and electrical performance are critical. Nonetheless, issues like sourcing materials sustainably remain. Many companies report difficulties in finding suppliers who meet quality standards. This highlights a need for improvement in the supply chain. Despite its benefits, there is still room for growth and education on how to implement graphite lining effectively in various sectors.

Related Posts

-

Unmatched Quality and Reliability in Best Graphite Natural Products from Trusted Chinese Manufacturers

-

7 Essential Tips for Choosing the Right Graphite Insulating Lining Paper

-

Why Choose Flexible Graphite Sheet for Your Gasket and Sealing Needs

-

How to Use Graphite Natural for Optimal Performance in Your Projects

-

Unlocking Performance Enhancements with Best Graphite Thermal Film Benefits

-

Exploring the Efficiency of Thermal Graphite Sheets: Key Benefits and Applications in Advanced Cooling Solutions