Exploring Innovative Alternatives to Graphite Gasket Sheets for Diverse Applications

As industries evolve and the demand for more efficient materials increases, the limitation of traditional Graphite Gasket Sheets becomes more evident. While graphite has long been celebrated for its superior thermal and chemical resistance, the search for innovative alternatives has gained significant momentum. This exploration is not merely a pursuit of novelty but a critical response to the pressing needs for enhanced performance, sustainability, and cost-effectiveness across diverse applications. In this blog, we will delve into alternative materials that promise to match or even exceed the capabilities of Graphite Gasket Sheets, examining their potential benefits, challenges, and applications. Join us as we uncover the future of sealing solutions, guided by advancements in technology and material science.

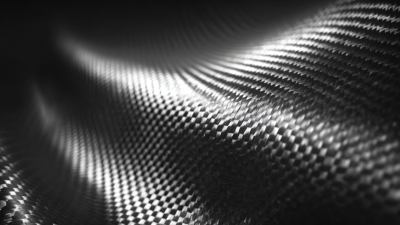

Exploring the Limitations of Traditional Graphite Gasket Sheets

Traditional graphite gasket sheets have long been a staple in various industrial applications due to their heat resistance and excellent sealing capabilities. However, they come with a set of limitations that can hinder their performance in certain environments. One significant drawback is their susceptibility to oxidation at high temperatures, which can lead to degradation over time. Additionally, graphite gaskets may not be suitable for aggressive chemical environments, as exposure to certain substances can compromise their integrity and sealing effectiveness.

Another limitation of traditional graphite gaskets is their tendency to be brittle, making them prone to cracking during installation or under mechanical stress. This fragility can result in frequent maintenance needs and increased downtime in operations where reliability is paramount. Furthermore, the environmental impact of mining and processing graphite raises concerns, pushing industries to seek sustainable alternatives.

Consequently, there is a growing interest in exploring innovative materials such as composite gaskets, PTFE-based products, and other advanced elastomers. These alternatives present new opportunities to enhance performance and sustainability while addressing the inherent limitations of graphite gasket sheets.

Innovative Materials Revolutionizing Gasket Solutions

The search for innovative materials in gasket technology is reshaping industries that rely on effective sealing solutions. Traditional graphite gasket sheets, while popular for their thermal resistance and durability, are gradually being overshadowed by advanced alternatives.

Materials such as PTFE, silicone, and even metal composite gaskets are taking center stage, offering enhancements in flexibility, chemical resistance, and overall performance. These innovative options cater to demanding applications across sectors like automotive, aerospace, and chemical processing, where high-temperature and high-pressure conditions are common.

Moreover, advancements in material science have paved the way for bio-based and eco-friendly gasket solutions, aligning with the global push for sustainability. Biomaterials can provide robust sealing properties while minimizing environmental impact, appealing to manufacturers targeting greener practices. The development of smart gaskets, integrated with sensors to monitor conditions in real-time, is another forefront of gasket innovation, ensuring safety and efficiency. As these materials revolutionize gasket solutions, industries are poised to benefit from improved reliability, longer lifespans, and reduced maintenance costs, heralding a new era in sealing technology.

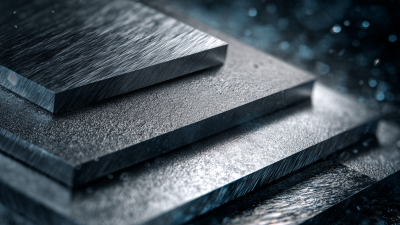

Applications of Advanced Composites in High-Temperature Environments

The demand for advanced composites in high-temperature applications is on the rise, as industries seek to improve performance while reducing weight and enhancing durability. Traditional graphite gasket sheets, while effective, have limitations that newer materials, such as ceramic composites and polymer matrix materials, can overcome. These alternatives offer superior resistance to extreme temperatures and corrosive environments, making them ideal for sectors such as aerospace, automotive, and energy.

When considering materials for high-temperature applications, it is important to assess the specific needs of your project. Here are a few tips: First, evaluate the thermal stability and chemical resistance of the materials being considered. Second, test the material's mechanical properties under simulated conditions to ensure it can withstand stresses and thermal cycling without failure. Lastly, consult with manufacturers to understand the latest developments in advanced composites, as ongoing innovations can provide you with the best possible solutions.

Utilizing advanced composites can lead to significant efficiencies and improvements in operational life. By prioritizing high-performance materials, businesses can achieve better reliability and lower maintenance costs, particularly in industries where failure is not an option. Exploring these innovative alternatives can ultimately position your operations at the forefront of technology and efficiency.

Eco-Friendly Alternatives for Sustainable Gasketing Solutions

As industries increasingly prioritize sustainability, the search for eco-friendly alternatives to traditional graphite gasket sheets has gained significant momentum. These alternatives not only help reduce environmental impact but also meet the diverse needs of various applications. Materials such as bio-based composites and recycled polymers are emerging as viable substitutes, offering the same level of performance while minimizing carbon footprints. These innovative solutions can be tailored to specific requirements, ensuring reliability in sealing without compromising on sustainability.

Moreover, the development of biodegradable gasket materials signifies a pivotal shift in how manufacturers approach gasketing solutions. For example, natural fibers like hemp or flax can be blended with sustainable resins, creating a gasket sheet that is not only effective but also compostable at the end of its life cycle. This aligns with the growing trend of circular economy practices, where waste is reduced, and materials are repurposed effectively. By investing in these cutting-edge options, companies can enhance their commitment to environmental responsibility while continuing to deliver high-quality products across various sectors.

Comparative Analysis: Graphite vs. Emerging Gasket Materials

As industries evolve, the demand for advanced sealing solutions has prompted a closer look at alternatives to traditional graphite gasket sheets. Graphite gaskets have long been favored for their excellent thermal resistance and compressibility; however, they do come with certain limitations, particularly related to environmental factors and lifespan under extreme conditions. Emerging materials, such as PTFE, silicone, and composite gaskets, are being explored for their unique properties that can outperform graphite in specific applications while offering enhanced durability and chemical resistance.

When comparing graphite to these innovative gasket materials, it's essential to consider factors like temperature tolerance, pressure thresholds, and fluid compatibility. For instance, PTFE gaskets are praised for their exceptional chemical resistance, making them ideal for applications involving aggressive substances. Meanwhile, silicone gaskets provide flexibility at high temperatures, catering to scenarios where thermal expansion is a concern. This comparative analysis reveals that while graphite has been a staple in gasket manufacturing, the rise of alternative materials presents exciting opportunities for improved performance and sustainability in diverse industrial applications.

Comparative Analysis of Graphite Gasket Sheets vs. Emerging Gasket Materials

Related Posts

-

Real-World Applications of the Best Graphite Gasket Sheet in Various Industries

-

Maximizing Value with Best Flexible Graphite Gaskets: After-Sales Support and Maintenance Cost Insights for a Sustainable Future

-

Exploring the Versatility of the Best Graphite Sheet: Unique Use Cases and Applications

-

5 Innovative Ways the Best Graphite Cooling Film Can Transform Your Technology

-

Understanding Industry Standards and Reasons Behind the Best Graphite Thermal Sheet Selection

-

7 Best Reasons to Choose Graphite Wall Paper for Your Next Renovation