7 Essential Tips for Choosing the Right Graphite Insulating Lining Paper

In today's rapidly evolving industrial landscape, the selection of high-performance materials is paramount, especially when it comes to ensuring efficiency and safety in various applications. Among these materials, Graphite Insulating Lining Paper has emerged as a crucial component, offering superior insulating properties and thermal stability. According to a recent market analysis, the demand for advanced insulation materials, including graphite products, is projected to grow at a compound annual growth rate (CAGR) of 6.5% through 2027, driven by increasing needs in the aerospace and automotive sectors. As industries strive for better energy efficiency and sustainability, understanding the unique characteristics and applications of Graphite Insulating Lining Paper becomes essential. This guide outlines seven essential tips for selecting the right type, helping engineers and procurement specialists navigate the complex landscape of insulating materials to achieve optimal performance and reliability.

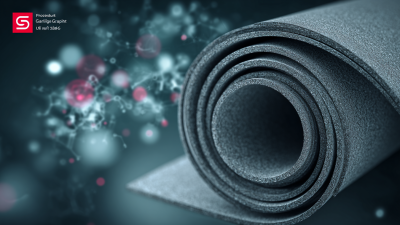

Understanding the Importance of Graphite Insulating Lining Paper in Industrial Applications

In industrial applications, graphite insulating lining paper plays a critical role in enhancing efficiency and safety. This specialized paper is designed to provide thermal insulation while also resisting electrical conductivity, making it ideal for environments where high temperatures and electrical currents are present. Its unique properties ensure that equipment remains protected from heat damage, which can extend the lifespan of machinery and reduce the need for frequent replacements or repairs.

Moreover, the use of graphite insulating lining paper can lead to significant energy savings. By effectively insulating components, it minimizes heat loss, allowing systems to operate at optimal temperatures. This not only helps in reducing operational costs but also contributes to sustainable practices by lowering energy consumption. As industries increasingly focus on efficiency and environmental responsibility, understanding the importance of selecting the right graphite insulating lining paper becomes crucial for achieving long-term operational success.

Key Factors to Consider When Selecting Graphite Insulating Lining Paper

When selecting graphite insulating lining paper, it's essential to consider several key factors to ensure you choose the right product for your specific needs. One important aspect is the thermal insulation capability of the material. Recent advancements in nanotechnology have led to the development of nanostructured insulations that offer superior thermal performance. Understanding how these materials perform in various environments will help in selecting the right insulation properties that align with your requirements.

Another critical factor is the structural integrity of the graphite composite papers. Innovations such as pressure-induced self-interlocked structures have shown significant improvements in shielding effectiveness while maintaining excellent thermal conductivity. When evaluating different products, look for options that not only provide effective insulation but also stand up to mechanical stress and environmental factors. Assessing both the thermal characteristics and the overall durability of the graphite insulating lining paper will lead to better performance and longevity in practical applications.

Comparison of Key Factors in Choosing Graphite Insulating Lining Paper

Different Types of Graphite Insulating Lining Papers and Their Uses

When it comes to selecting the right graphite insulating lining paper, understanding the various types available can greatly influence your decision. Graphite insulating lining papers are primarily categorized based on their thermal resistance, thickness, and application area. For instance, high-temperature graphite papers are designed to withstand extreme heat, making them ideal for industrial furnaces or hazardous environments. These papers not only provide excellent insulation but also contribute to energy efficiency by minimizing heat loss.

In contrast, flexible graphite insulating papers are often used in applications requiring adaptability and resistance to chemicals. Their enhanced flexibility allows them to conform to different surfaces, making them suitable for use in sealing and gaskets. Additionally, there are specialty graphite papers embedded with additives to enhance conductivity or to improve mechanical strength. Identifying the specific requirements of your project will help in choosing the right type of graphite insulating lining paper, ensuring optimal performance and longevity.

How to Assess the Quality of Graphite Insulating Lining Materials

When evaluating the quality of graphite insulating lining materials, it is essential to consider several key factors that determine their performance and durability. First, examine the purity of the graphite used in the lining material. Higher purity levels often correlate with better thermal and electrical insulating properties, which are crucial in high-performance applications. You should also look for certifications or laboratory test results that validate the material's quality and compliance with industry standards.

Another important aspect is the construction and thickness of the lining paper. Thicker materials generally provide better insulation and resistance to wear and tear. Assessing the manufacturing process is also critical; materials that undergo rigorous testing and quality control processes are more likely to maintain their functionality over time. Furthermore, consider the thermal conductivity ratings provided by the manufacturer, as these will give you a clear idea of how effectively the material will insulate against heat transfer in your specific application. By focusing on these factors, you can make informed decisions that ensure optimal performance in your projects.

| Tip | Description | Quality Indicator | Importance Level |

|---|---|---|---|

| 1. Material Composition | Check the materials used to ensure high thermal resistance. | High-grade graphite, minimal impurities | Critical |

| 2. Thickness | Evaluate the thickness for desired insulation performance. | Specified thickness range | High |

| 3. Thermal Conductivity | Assess the thermal conductivity rating to ensure effectiveness. | Low thermal conductivity value | Critical |

| 4. Surface Finish | Verify the finish for uniformity and adhesion potential. | Smooth and even surface | Moderate |

| 5. Temperature Resistance | Look for rated temperature limits for operational safety. | High temperature tolerance | High |

| 6. Chemical Resistance | Ensure the lining withstands potential chemical exposure. | Resistant to common chemicals | Moderate |

| 7. Certification and Standards | Check for compliance with industry standards. | ISO or ASTM certification | Critical |

Cost Considerations: Balancing Quality and Budget for Insulating Paper Choices

When selecting graphite insulating lining paper, cost considerations are as vital as the quality of the materials. The market for insulating papers is projected to grow significantly, with a CAGR of about 5.2% from 2021 to 2026, according to a recent report by Research and Markets. This growth is driven by increasing demands in industries such as electronics, automotive, and energy; thus, balancing quality and budget is crucial for manufacturers and engineers alike.

Investing in higher-quality graphite insulating lining papers can provide long-term savings by enhancing energy efficiency and reducing maintenance costs. For instance, premium-grade insulating papers typically exhibit lower thermal conductivity, resulting in better insulation and lower heating expenses—a key factor for industries aiming to cut down on operational costs. A study from the International Journal of Industrial Technology highlighted that using high-quality insulating materials could improve equipment efficiency by up to 15%. Therefore, while it's essential to consider immediate budgets, an informed approach toward selecting insulating paper can yield substantial returns in the future.

Investing in higher-quality graphite insulating lining papers can provide long-term savings by enhancing energy efficiency and reducing maintenance costs. For instance, premium-grade insulating papers typically exhibit lower thermal conductivity, resulting in better insulation and lower heating expenses—a key factor for industries aiming to cut down on operational costs. A study from the International Journal of Industrial Technology highlighted that using high-quality insulating materials could improve equipment efficiency by up to 15%. Therefore, while it's essential to consider immediate budgets, an informed approach toward selecting insulating paper can yield substantial returns in the future.

Related Posts

-

Unmatched Quality and Reliability in Best Graphite Natural Products from Trusted Chinese Manufacturers

-

Overcoming the Challenges of Using Best Graphite Paper Officeworks in Your Projects

-

Exploring Unique Alternatives to Best Graphite Paper Staples for Your Crafting Needs

-

Challenges Faced by Industries When Using Flexible Graphite Sheets

-

Ultimate Guide to Sourcing Thermal Graphite Sheets for Enhanced Thermal Management Solutions

-

Exploring Future Innovations in Best Flexible Graphite Gasket Technology for 2025