Exploring the Efficiency of Thermal Graphite Sheets: Key Benefits and Applications in Advanced Cooling Solutions

The increasing demand for efficient heat management in modern technology has led to the exploration of innovative materials, among which the Thermal Graphite Sheet stands out as a frontrunner. This advanced material, known for its remarkable thermal conductivity, offers unparalleled performance in cooling solutions across various applications, from consumer electronics to industrial machinery. The unique properties of Thermal Graphite Sheets enable them to effectively dissipate heat, ensuring optimal operational efficiency and longevity of components. As industries strive to meet stringent thermal management requirements while enhancing product reliability, understanding the key benefits and applications of Thermal Graphite Sheets becomes paramount. This exploration not only highlights their role in advanced cooling solutions but also positions them as essential components in the evolution of cutting-edge technologies.

Benefits of Thermal Conductivity in Graphite Sheets for Cooling Solutions

The advancements in thermal management technologies have brought thermal graphite sheets to the forefront, especially in cooling applications for electronics and other high-performance systems. These sheets boast exceptional thermal conductivity, with values often exceeding 1500 W/m·K, making them ideal for dissipating heat efficiently. According to a recent market report, the demand for thermal interface materials, including graphite sheets, is projected to grow at a CAGR of 9.8%, highlighting their crucial role in thermal management strategies.

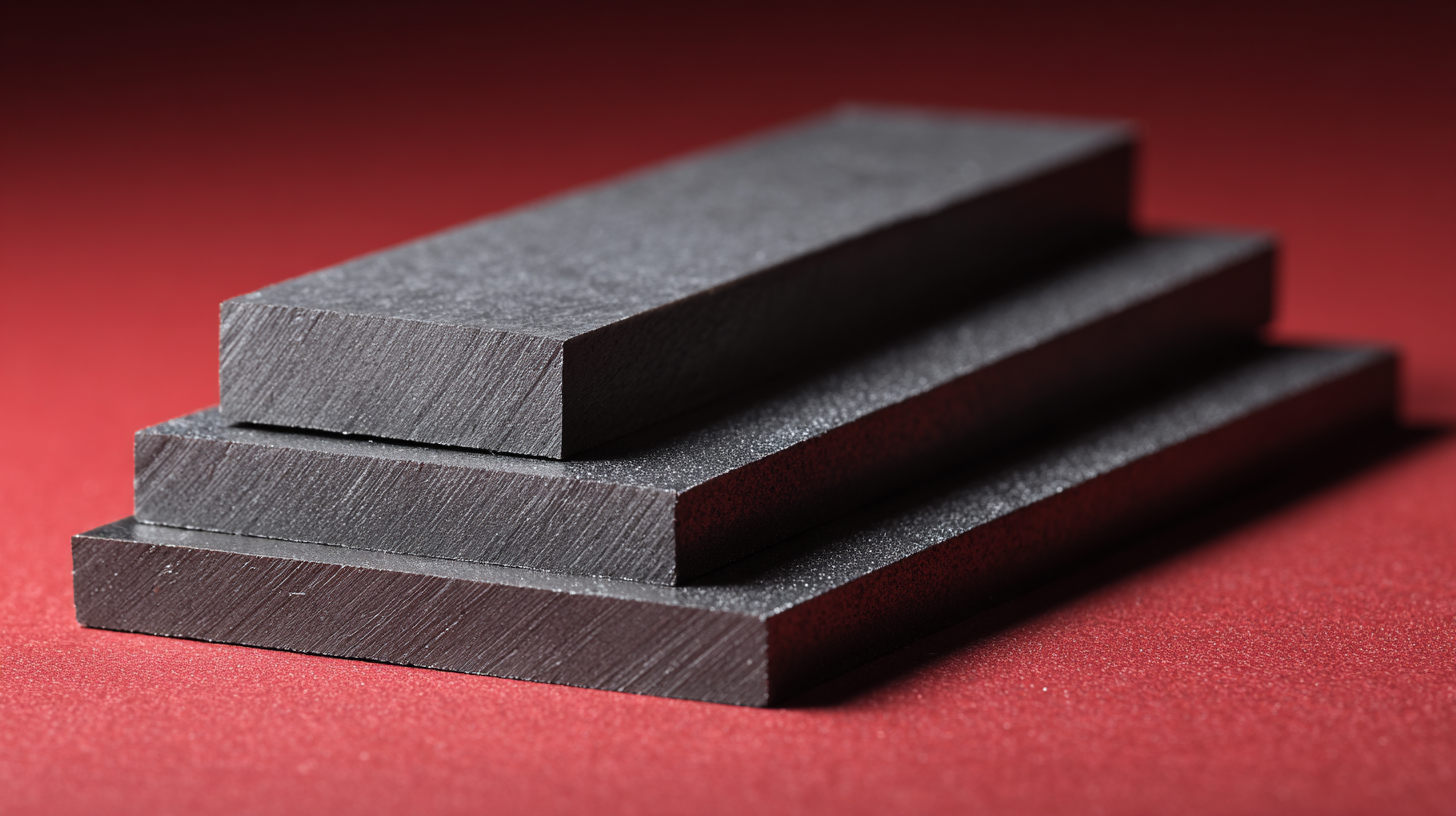

One of the standout benefits of thermal graphite sheets is their lightweight nature combined with excellent mechanical properties, which means they can be integrated into various compact designs without adding significant bulk. They also exhibit a high degree of thermal stability, performing well under temperature fluctuations. This capability is particularly advantageous in applications like LED lighting and electric vehicles, where overheating can severely impact efficiency and lifespan.

**Tip:** When selecting thermal graphite sheets for your application, consider the alignment of the graphite flakes; the thermal conductivity can vary greatly based on the orientation, with planar sheets outperforming their isotropic counterparts. Additionally, ensure compatibility with other materials in your design to leverage their full potential.

Exploring the Efficiency of Thermal Graphite Sheets in Cooling Solutions

This chart illustrates the key parameters associated with thermal graphite sheets used in advanced cooling solutions, showcasing their exceptional thermal conductivity, weight characteristics, typical thickness, and cost per square meter.

Key Performance Metrics: Comparing Thermal Graphite Sheets with Conventional Materials

The rising demand for advanced cooling solutions in electronics has drawn attention to the efficiency of thermal graphite sheets. These materials not only exhibit superior thermal conductivity compared to conventional materials but also offer enhanced flexibility and lightweight properties, making them ideal for various applications in high-performance environments. In particular, the thermal management capabilities of graphite sheets are critical in cutting-edge devices, where heat dissipation is paramount to ensuring reliability and performance.

Tips: When selecting thermal management materials, consider both thermal conductivity and the mechanical properties necessary for your application. High-performance polymer fabrics can also complement thermal graphite sheets, providing additional durability and flexibility. Additionally, incorporating phase change materials can further enhance thermal efficiency by effectively storing and releasing energy.

In comparison to traditional materials, thermal graphite sheets provide a more efficient solution for thermal conductivity, enabling better performance in devices like wearable technologies and high-power RF systems. Their unique properties make them an excellent choice for engineers looking to push the boundaries of thermal management in next-generation applications.

Applications of Graphite Sheets in Electronics and Renewable Energy Cooling Systems

The application of graphite sheets in electronics and renewable energy cooling systems is gaining traction, driven by the need for efficient heat management solutions. As technology evolves, the demand for advanced cooling solutions in high-performance electronic devices is surging. Graphite sheets, known for their excellent thermal conductivity, serve as an ideal thermal interface material (TIM) that enhances heat dissipation in electronics. Recent studies highlight the significance of thermal interface materials in regulating temperatures in devices, ensuring they operate within optimal thermal limits.

In the renewable energy sector, the integration of graphite sheets shows promise in improving the efficiency of solar thermal energy systems. Experimental research indicates that the incorporation of materials such as graphene nanoplatelets can significantly enhance the thermal behavior and energy storage capabilities of phase change materials (PCMs). With the projected growth of the flexible graphite market, expected to increase from USD 0.35 billion in 2025 to USD 0.45 billion by 2030, it is evident that graphite’s role in these applications is not only pivotal but also economically promising. The confluence of advanced materials like graphite sheets and innovative applications in cooling systems positions them at the forefront of technological advancements in both electronics and renewable energy domains.

Cost-Effectiveness and Sustainability of Using Graphite Sheets in Cooling Technologies

The adoption of thermal graphite sheets in cooling technologies presents a compelling case for cost-effectiveness and sustainability. Graphite sheets, with their exceptional thermal conductivity, offer a significant reduction in energy consumption compared to traditional cooling methods. By efficiently dissipating heat, these materials minimize the need for additional power-hungry cooling systems, leading to reduced operational costs. Businesses can experience substantial savings in energy bills while maintaining optimal performance levels, making thermal graphite sheets an economical choice for both large-scale enterprises and small manufacturers.

Moreover, the sustainability aspect of using graphite sheets cannot be overlooked. Graphite, being a naturally abundant material, reduces the ecological footprint associated with manufacturing cooling solutions. Additionally, these sheets have a long lifespan and are recyclable, which aligns with the growing demand for environmentally friendly products in the industry. By integrating thermal graphite sheets into cooling systems, companies not only prioritize efficiency and savings but also contribute to a more sustainable future, emphasizing the importance of innovation in balancing technological advancement with environmental responsibility.

Exploring the Efficiency of Thermal Graphite Sheets: Key Benefits and Applications in Advanced Cooling Solutions

| Dimension | Value |

|---|---|

| Thermal Conductivity (W/m·K) | 1500 |

| Thickness (mm) | 0.5 - 3.0 |

| Density (g/cm³) | 1.8 |

| Specific Heat (J/kg·K) | 800 |

| Operating Temperature Range (°C) | -40 to 250 |

| Application Areas | Electronics, Automotive, HVAC |

| Cost per Square Meter ($) | 50 |

| Lifespan (years) | 10 |

| Environmental Impact | Low |

Future Trends: Innovations in Graphite Sheet Manufacturing and Design for Enhanced Cooling Efficiency

The future of thermal graphite sheet manufacturing is poised for significant innovations aimed at enhancing cooling efficiency across various industries. Recent advancements focus on the incorporation of advanced composites and nanomaterials, which not only improve thermal conductivity but also reduce weight and thickness. These innovations enable the design of slimmer cooling solutions that do not compromise on performance, making them ideal for applications in high-performance electronics, electric vehicles, and aerospace.

Furthermore, the development of automated manufacturing techniques promises to streamline production processes, leading to cost-effective solutions without sacrificing quality. Customization options are also on the rise, allowing manufacturers to tailor graphite sheets to specific thermal management needs and environmental conditions. With a growing emphasis on sustainability, new eco-friendly materials are being explored, ensuring that the production of thermal graphite sheets aligns with global efforts toward reducing environmental impact. These trends indicate a promising future for thermal graphite technology, potentially setting new standards in cooling efficiency and application versatility.

Related Posts

-

Maximizing Value with Best Thermal Graphite Sheets: Service Benefits and Future Repair Innovations

-

Unlocking the Potential of Thermal Graphite Sheets: The Future of Efficient Heat Management

-

Exploring the Future of Graphite and Carbon Papers at China's 138th Canton Fair 2025: Industry Insights

-

How to Use Graphite Paper Staples for Effective Drawing and Design

-

Exploring the Future: Advances in Graphite Thermal Film Technology by 2025

-

Innovative Solutions for Graphite Paper Spotlight in Precision Manufacturing