Understanding the Advantages of Flexible Graphite Sheet in High Temperature Applications

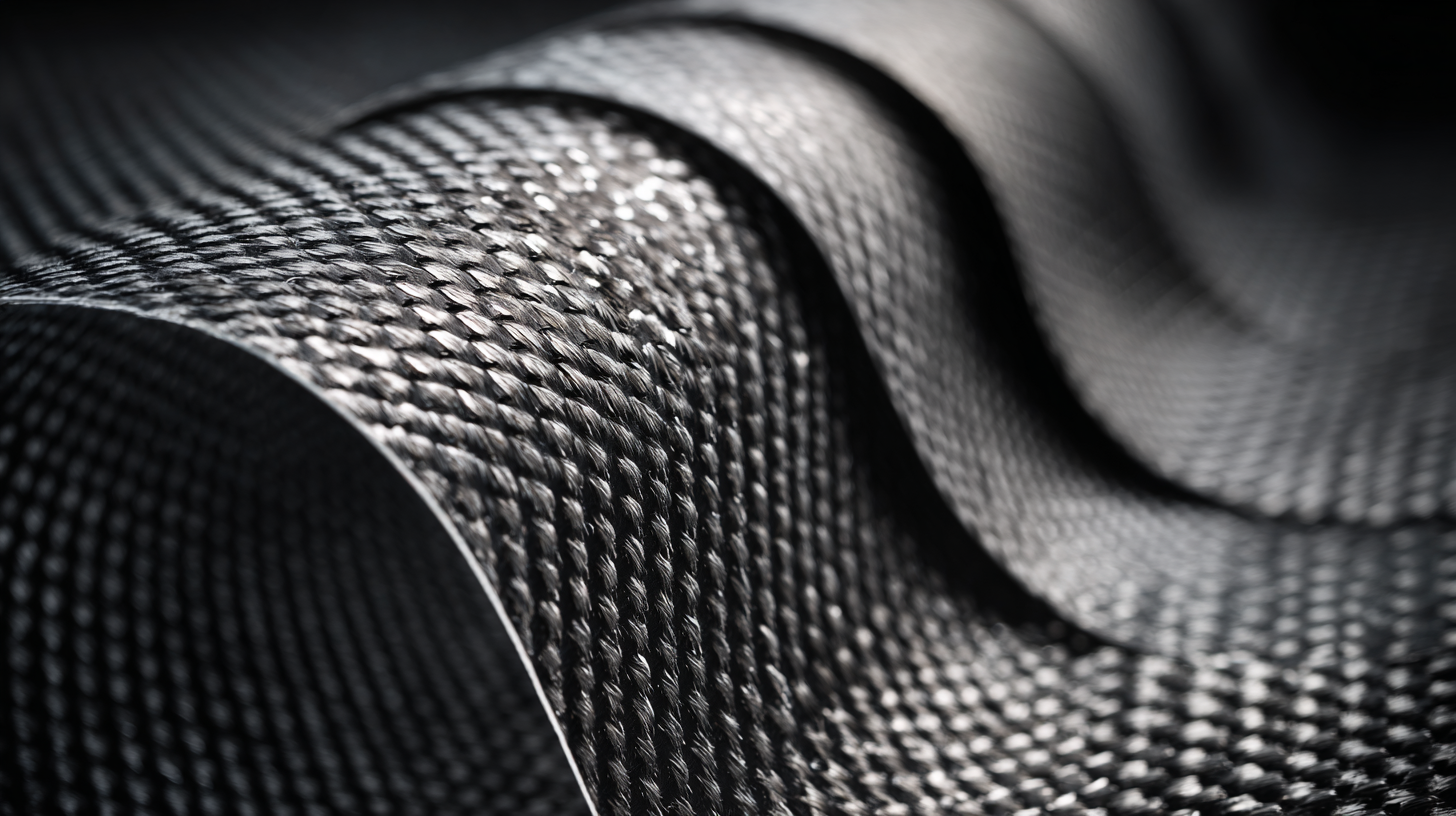

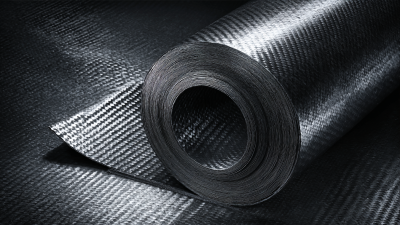

In the realm of high temperature applications, the demand for efficient heat management solutions has escalated, driving innovation in materials science. One of the standout solutions is the "Flexible Graphite Sheet", known for its remarkable thermal conductivity and resistance to chemical degradation. According to a report by MarketsandMarkets, the global market for flexible graphite materials is projected to reach USD 1.8 billion by 2025, underscoring its increasing adoption across various industries. The flexibility and reliability of graphite sheets make them ideal for applications in aerospace, automotive, and power generation, where they can withstand extreme temperatures without compromising performance. By leveraging the unique properties of Flexible Graphite Sheets, industries can significantly enhance their operational efficiency and extend the lifespan of critical components, making them indispensable in modern high temperature environments.

The Thermal Stability of Flexible Graphite Sheets at Elevated Temperatures

Flexible graphite sheets exhibit remarkable thermal stability at elevated temperatures, making them ideal for high-temperature applications across various industries. Their structural integrity enables them to maintain performance even when exposed to extreme heat, where traditional materials might fail. This resilience is critical in applications such as aerospace and automotive, where thermal management is paramount. Reports indicate that the flexible graphite market is projected to grow from USD 0.35 billion in 2025 to USD 0.45 billion by 2030, reflecting an annual growth rate of 5.5%. Such growth underscores the increasing reliance on flexible graphite for crucial thermal applications.

Current advancements in material science, particularly the study of expanded graphite and its composites, further highlight the importance of flexible graphite sheets in modern engineering. For instance, research shows that combining expanded graphite with epoxy resin can enhance thermal conductivity without compromising mechanical properties, paving the way for innovative thermal interface materials. This aligns with the industry's push towards advanced heat-dissipating materials essential for aerospace applications, where effective thermal management systems are not just beneficial, but necessary for operational safety and efficiency.

Performance Advantages of Flexible Graphite in Extreme Thermal Environments

Flexible graphite sheets are increasingly recognized for their superior performance in high-temperature applications, especially in extreme thermal environments. These materials possess an exceptional thermal conductivity and stability that allow them to maintain performance under severe conditions, making them ideal for applications in industries such as aerospace, automotive, and energy production. The unique properties of flexible graphite enable it to withstand temperatures that would typically degrade other materials, thereby extending the lifespan of components and reducing maintenance needs.

The growing interest in flexible graphite is mirrored in the market's expansion, with projections indicating significant growth from USD 0.35 billion in 2025 to USD 0.45 billion by 2030. This growth is driven by the increasing demand for materials that effectively manage thermal energy, including advanced phase change materials (PCMs) used for energy storage. Additionally, recent developments such as joint ventures in expandable graphite production highlight the rising importance of flexible graphite in the global market, as industries seek reliable alternatives to overcome supply challenges. Through its unique characteristics and performance advantages, flexible graphite continues to shape the future of thermal management solutions in extreme environments.

Comparative Analysis: Flexible Graphite vs. Traditional Materials in High Heat Applications

Flexible graphite sheets offer several advantages over traditional materials when it comes to high-temperature applications. Their unique structure enables them to withstand severe thermal conditions without losing integrity, making them ideal for use in environments where temperature fluctuations are a concern. In contrast, traditional insulating materials often fail to perform effectively under similar conditions, leading to reduced efficiency and potential equipment failure. This comparative resilience positions flexible graphite as a superior choice in various industrial applications.

Moreover, the versatility of flexible graphite sheets allows for easier integration into complex systems compared to traditional materials. This adaptability not only enhances thermal management but also contributes to weight reduction in designs where every gram matters. As industries increasingly seek innovative solutions to meet the demands of high-performance environments, the shift towards flexible graphite is likely to accelerate, reinforcing its status as a key material in modern manufacturing processes.

Comparative Analysis of Material Performance in High Temperature Applications

Applications of Flexible Graphite Sheets in Industries Facing High Temperature Challenges

Flexible graphite sheets have become essential in various industries that face high-temperature challenges, such as aerospace, automotive, and power generation. Their outstanding thermal resistance and mechanical properties make them ideal for applications where traditional materials may fail. These sheets can withstand extreme conditions, providing reliable sealing, insulation, and thermal management solutions that help improve operational efficiency and extend equipment life.

Tips for selecting flexible graphite sheets include assessing the specific temperature range and environmental conditions of your application. Additionally, consider the thickness and density of the graphite sheet to ensure optimal performance under stress. Implementing quality control measures during the manufacturing process can also enhance the longevity of these materials in high-temperature scenarios.

As the flexible graphite market is projected to reach USD 0.45 billion by 2030, industries must stay informed about these advancements. Understanding how flexible graphite sheets can be tailored for specific uses can guide businesses in making strategic decisions that align with their operational needs and budgets. Emphasizing the importance of reliable materials in high-stakes environments will ultimately drive growth and innovation in the sector.

Understanding the Advantages of Flexible Graphite Sheet in High Temperature Applications

| Application Area | Temperature Range (°C) | Advantages | Industries |

|---|---|---|---|

| Oil and Gas Exploration | -50 to 200 | Excellent thermal conductivity, chemical resistance | Energy, Petrochemicals |

| Aerospace Components | -40 to 300 | Lightweight, strong, high temperature stability | Aerospace, Defense |

| Power Generation | -30 to 250 | Sealing properties, durability | Electricity, Nuclear |

| Chemical Processing | -50 to 200 | Corrosion resistance, high density | Chemicals, Pharmaceuticals |

| Automotive Applications | -20 to 250 | High thermal resistance, flexible installation | Automotive, Transportation |

Cost Efficiency of Using Flexible Graphite Sheet in Long-term High Temperature Solutions

The flexible graphite sheet has emerged as a highly efficient solution for high-temperature applications, driven by its excellent thermal and chemical stability. As industries increasingly seek durable materials that can withstand extreme temperatures, the role of flexible graphite sheets becomes even more pronounced. These sheets demonstrate superior performance by maintaining their integrity in harsh environments, contributing to enhanced operational efficiency. This resilience not only protects equipment but also reduces maintenance costs, making flexible graphite sheets a cost-effective choice for long-term applications.

In terms of cost efficiency, investing in flexible graphite sheets can lead to significant savings over time. Their longevity translates into fewer replacements, while the reduction in downtime due to maintenance or failures further optimizes operational budgets. As the flexible graphite market is projected to grow steadily, reaching an estimated USD 0.45 billion by 2030, industries are recognizing the financial benefits of switching to these materials. The low thermal expansion and high thermal conductivity characteristics of flexible graphite also enhance energy efficiency, proving that this material not only meets high-performance standards but also aligns with the economic goals of businesses looking for sustainable long-term solutions.

Related Posts

-

What is Flexible Graphite Sheet and How It Revolutionizes Industrial Applications?

-

Innovative Applications of Flexible Graphite Sheet in High Performance Industries

-

Top 10 Thermal Graphite Sheet Manufacturers from China at the 137th Canton Fair

-

Unlocking Superior Performance with Best Flexible Graphite Sheets from Leading Chinese Manufacturers

-

Innovative Solutions for Graphite Paper Spotlight in Precision Manufacturing

-

What is Carbon Graphite Foil and Its Unique Applications in Industry