2026 Best Carbon Graphite Sheet Options: Ultimate Buying Guide

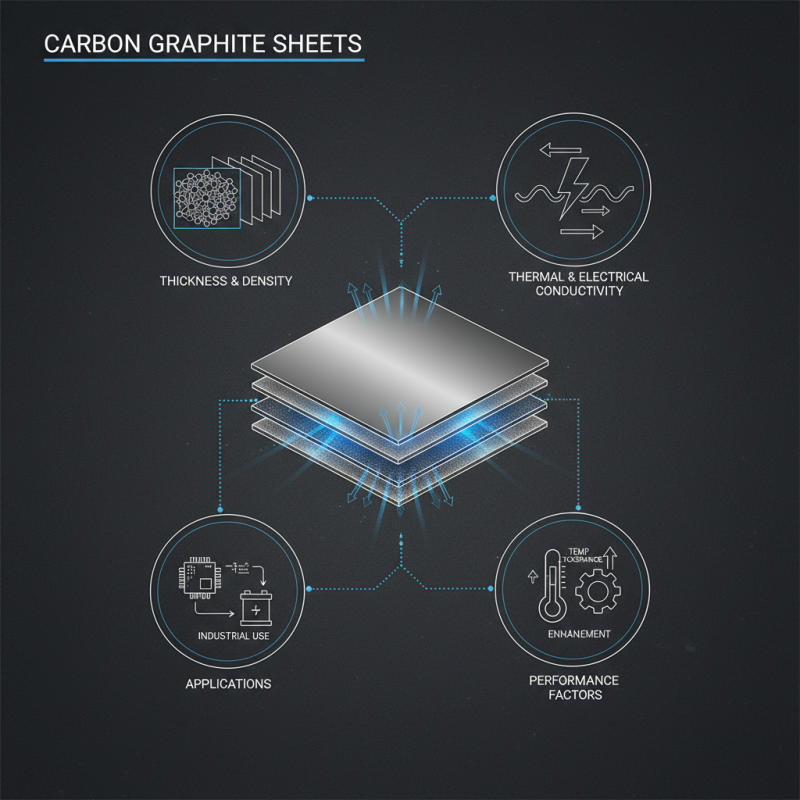

In the world of industrial materials, Carbon Graphite Sheets play a crucial role. These sheets offer excellent thermal and electrical conductivity. Their versatility makes them suitable for various applications. However, choosing the right option can be challenging.

This buying guide highlights the best Carbon Graphite Sheet options for 2026. It explores factors such as thickness, density, and price. With numerous brands available, making an informed decision is essential. Some products shine brightly, while others may disappoint. Reviewing each option carefully fosters better choices.

Remember, not every Carbon Graphite Sheet will meet your needs perfectly. Always consider specific requirements, such as temperature tolerance and application type. The right sheet should enhance performance, not hinder it. Engage in thorough research for a more rewarding experience.

Understanding Carbon Graphite Sheets: Composition and Properties

Carbon graphite sheets are crucial in various industries. They are made from carbon fibers and exhibit unique properties. These sheets provide excellent thermal conductivity. Their ability to withstand high temperatures makes them suitable for demanding applications.

One key property is their strength-to-weight ratio. Carbon graphite sheets are lightweight yet remarkably strong. According to industry data, these materials can endure stress better than many metals. Their resistance to corrosion is another essential benefit. Some reports state that they are less prone to degradation compared to traditional materials.

**Tip**: Always assess the thickness and density of the sheets you need. Different applications may require specific measurements to ensure performance.

Many users overlook the importance of proper installation. A gap or misalignment can lead to failures in critical applications. Some studies suggest that improper handling can reduce the sheet's effectiveness by up to 30%. Ensuring correct placement can save time and costs in the long run.

**Tip**: Consider ambient conditions before installation. Temperature and humidity can impact performance significantly.

Understanding the composition of carbon graphite sheets can lead to better sourcing decisions. Many variables affect the final product's quality. Knowing your application can guide you to the most suitable option.

Key Factors to Consider When Choosing Carbon Graphite Sheets

When selecting carbon graphite sheets, several key factors play a significant role in making the right choice. The thickness of the sheet can impact its performance. Thicker sheets often provide better durability. However, they can be heavier and less flexible. You must find a balance that meets your specific needs.

Another important consideration is the material grade. Different grades offer various properties. High-quality grades often have superior thermal and electrical conductivity. However, they may be more expensive. It may lead to second thoughts about budget constraints. It's essential to weigh the pros and cons carefully.

The intended application of the sheets also matters. Are they for industrial use or personal projects? For instance, sheets meant for high-pressure applications need to withstand greater stress. On the other hand, if flexibility is crucial, lighter options might be better. Evaluate your requirements thoroughly. Sometimes, the simplest choice can be the most effective.

2026 Best Carbon Graphite Sheet Options

This chart represents the performance characteristics of different carbon graphite sheets in terms of thermal conductivity, electrical conductivity, and tensile strength. This information can help you make an informed decision when selecting a carbon graphite sheet for your needs.

Comparative Analysis of Top Carbon Graphite Sheet Brands in 2026

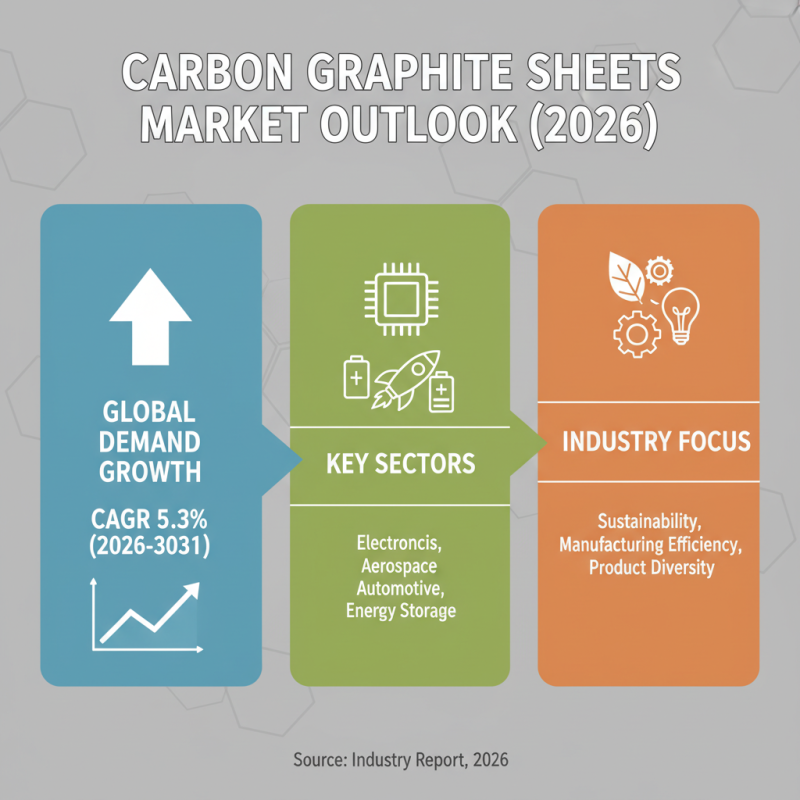

In 2026, the market for carbon graphite sheets is evolving rapidly. A recent industry report highlights that the global demand for these materials is projected to grow at a CAGR of 5.3% over the next five years. This growth indicates a significant increase in applications across various sectors, from electronics to aerospace. Many companies are emphasizing sustainability and manufacturing efficiency, but the diversity of products can be overwhelming.

When comparing options, material purity is crucial. Research shows that sheets with over 99% carbon content perform better in high-temperature applications. However, not all sheets meet this standard. Some manufacturers cut corners, leading to inconsistent quality. This inconsistency can affect performance in critical applications, making it essential for buyers to double-check specifications.

Another aspect to consider is thickness variations. While thicker sheets often offer better performance, they can also be more challenging to work with. Sourcing the right thickness requires understanding project needs and application requirements. Online forums indicate that many users struggle to find a precise balance between durability and ease of installation. Feedback loops with suppliers could provide insights but often reveal gaps in communication. As the landscape shifts, staying informed will be key to making the right choices.

Application Areas and Industry Demands for Carbon Graphite Sheets

Carbon graphite sheets are increasingly popular in various industries. Their ability to withstand high temperatures and offer excellent lubricating properties makes them ideal for numerous applications. Industries such as automotive, aerospace, and electronics utilize these sheets for seals, gaskets, and insulation.

In the automotive sector, carbon graphite sheets are used in engine components. They help improve efficiency and reduce friction. This leads to better fuel economy. In aerospace, the lightweight nature of these sheets reduces the overall weight of aircraft. This can improve flight performance and reduce emissions.

Tips: When selecting carbon graphite sheets, consider their thickness and density. Different applications require varying specifications. Always test the sheets under real conditions to ensure they meet your needs.

The electronics industry benefits from carbon graphite sheets as well. They provide thermal conductivity for cooling applications. However, compatibility with other materials is essential, as some combinations can lead to a failure. It's crucial to research and experiment with different materials to find the best pairing.

Technical Specifications and Performance Metrics for Carbon Graphite Sheets

When selecting carbon graphite sheets, understanding their technical specifications is crucial. These sheets vary in thickness, density, and thermal conductivity. Most high-quality options exhibit densities ranging from 1.5 g/cm³ to 1.9 g/cm³. This density directly impacts their mechanical strength and durability.

Performance metrics should also be considered. The thermal conductivity of carbon graphite sheets can reach up to 200 W/mK. This makes them ideal for heat dissipation applications. Be mindful, however, that not all sheets meet this standard. Some may fall below 150 W/mK, leading to inefficiencies in high-temperature environments.

Additionally, it's important to assess the compressive strength. Many sources highlight figures around 40 MPa, but some products may offer significantly lower resistance. This could result in performance issues in applications demanding durability. Always request detailed specifications to avoid surprises. Discrepancies in properties can lead to project delays or failures.

Related Posts

-

Unlocking Superior Performance with Best Flexible Graphite Sheets from Leading Chinese Manufacturers

-

How to Choose the Best Natural Graphite Sheet for Your Applications

-

Ultimate Guide to Sourcing Flexible Graphite Packing for Optimal Performance and Reliability

-

2025 Top 10 Graphite Carbon Paper Options for Every Artist and Printer

-

Discover the Superior Benefits of Choosing Best Natural Flake for Your Business Needs

-

Global Market Trends and Insights for Best Graphite Paper by 2025 with Real World Applications